Technologies

Nuton Technologies—Engineering a step change

Our suite of nature-based technologies could reshape the copper mining industry. Our cutting-edge bioleaching process is at the heart of this transformation.

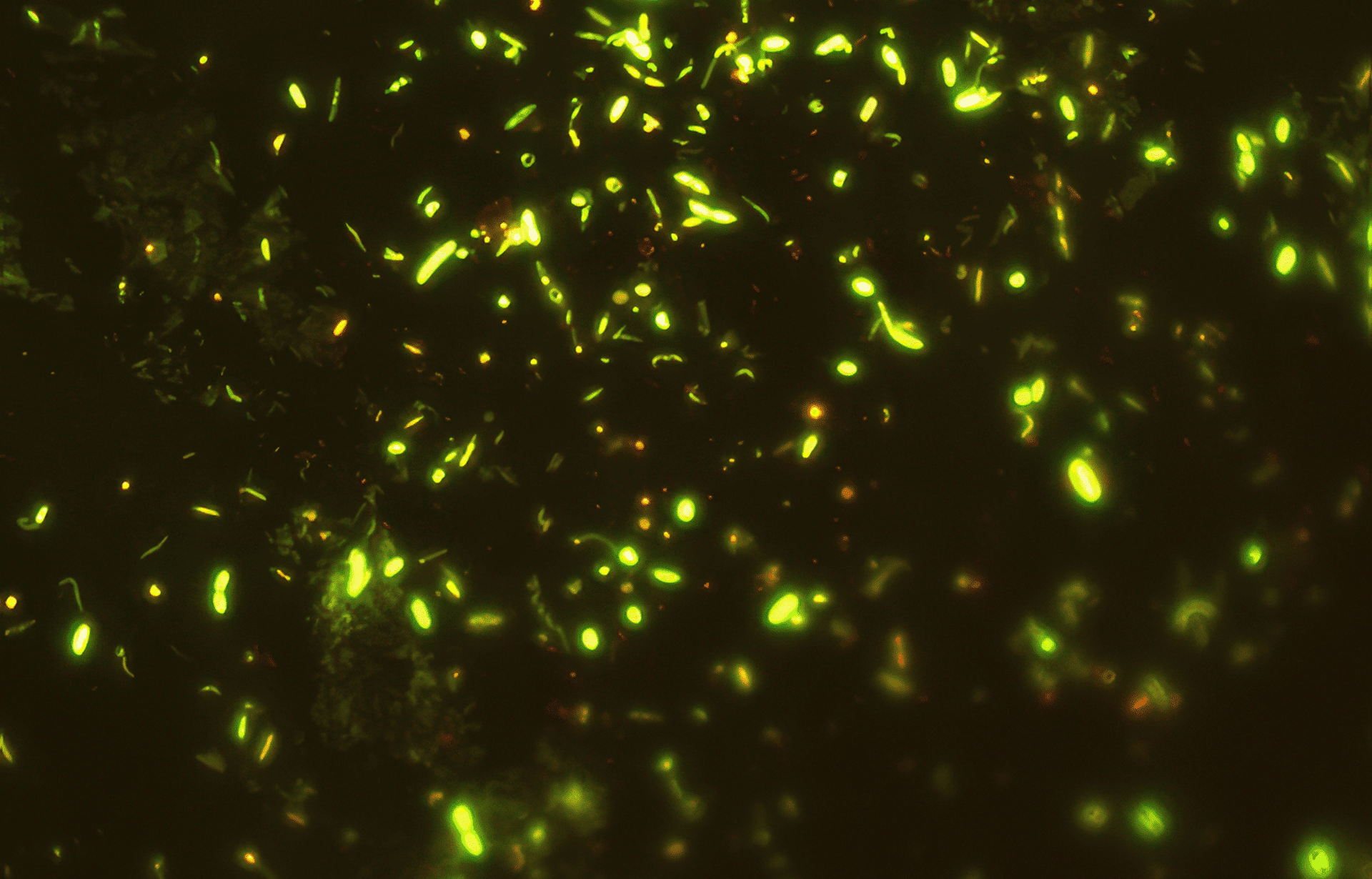

We harness the power of bacteria to extract copper from primary sulphides, minerals that make up more than 70% of the world’s copper reserves. Conventional leaching methods have well-known limitations when applied to primary sulphide ores. The Nuton technologies have the potential to change the game by making historically difficult-to-leach sulphide ores economically viable. We accomplish this by achieving industry-leading copper recovery rates of up to 85%, surpassing current industry norms.

At Nuton, we understand that one size does not fit all. In collaboration with our partners, we tailor our deployment plans to account for specific site mineralogy, geography, and other conditions. Along with unlocking more copper, this customized approach can deliver benefits such as smaller production footprints, improved environmental, social and governance (ESG) performance and decreased production costs.

The Nuton Process

“

Nuton, our heap leaching technology, is an enabler for low-carbon copper – a testament to decades of Rio Tinto’s in-house research and development.

Clayton Walker, Chief Growth & Development Officer – Americas, Copper

”

Bacteria magic – lower economic costs and environmental impacts

Using bacteria to extract copper from primary sulphide ores through heap leaching can cost less and create a smaller environmental footprint than conventional mining processes. Through our in-house product research we have nurtured naturally occurring microorganisms capable of doing incredible things.

Higher yield on primary and waste ores

With recovery rates of up to 85% – well above current industry norms – Nuton Technologies produce more copper than traditional leaching processes from the same volume of ore processed. And they’re also effective, both in cost and yield, with materials like pyrite that might otherwise be considered waste, or an economic liability to mine.

Versatile applications

Whether working with brownfield sites, greenfield sites, or legacy mines, we can tailor solutions that can facilitate the recovery of higher rates of copper from complex materials and in technically challenging, previously cost-prohibitive settings.

“

Rio Tinto’s multi-decade investment in heap leach process development is a critical enabler for unlocking copper growth. Success relies on close collaboration. The collaborative approach between Rio Tinto’s technical development centre and the Nuton™ Venture team is enabling Nuton to move with speed and continue to enhance the technology performance.

Jared

GM Technical Development Rio Tinto

”

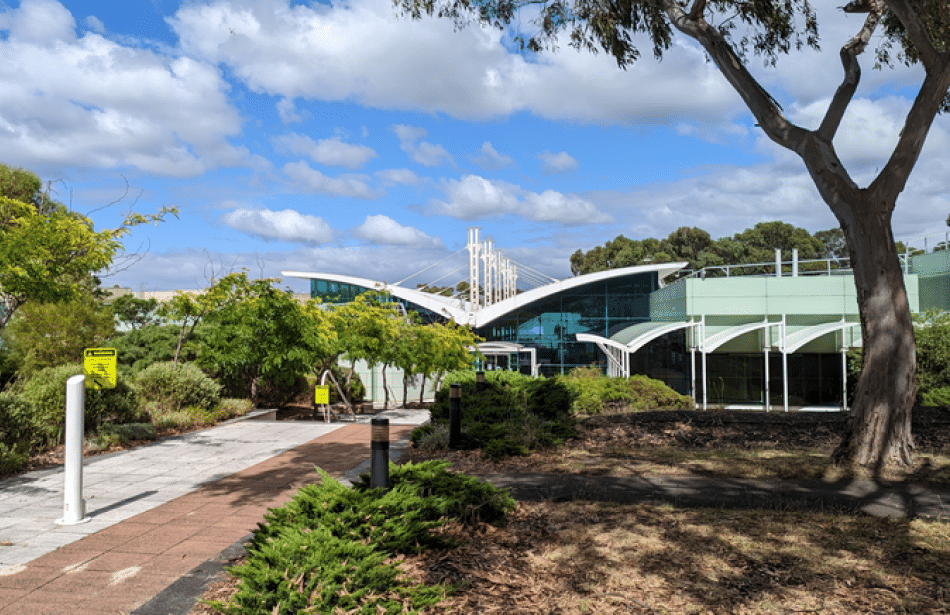

Bundoora collaboration

Rio Tinto’s Bundoora Technical Development Center in Melbourne, Australia, has been researching and developing the scientific breakthroughs that make Nuton technologies possible. Over 3 decades, Bundoora has worked across the full breadth of Rio Tinto’s commodities and assets to deliver value via technical developments. For Nuton, this means advancements in copper sulphide heap leaching process development and modelling capabilities that reduce the requirement for extensive test programs.

Copper production at your site

Whether you are looking to unlock more copper from a greenfield or brownfield site, or a legacy mine, Nuton Technologies bring the potential of reduced timelines, environmental impacts, and costs.