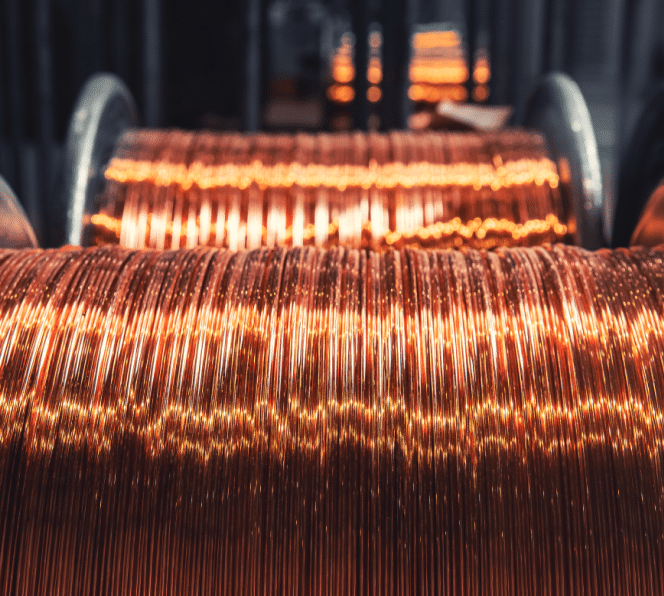

Nuton’s Positive Impact Ambition

Finding better ways

We advocate for a new way of doing business that positively contributes to society, the environment, and the economy. Beyond mitigating risks or reducing harm, we champion the idea that businesses can and should have a responsibility to regenerate and restore the systems they depend on.

Our Positive Impact ambition

At Nuton, we aim to produce the world’s lowest footprint copper while having at least one Positive Impact at each of our deployment sites, across our five pillars: water, materials, energy, land and society.

As a technology venture, we don’t operate mines directly, so most of our footprint originates outside typical business boundaries. For this reason, achieving our Positive Impact ambition requires close collaboration and strong partnerships with our mining partners. At each site, we’ll work with you to select a pillar to focus our efforts, bringing the ambition to life through a robust plan and transparent metrics to track progress.

We have defined what achieving a Positive Impact means for each of our pillars, and have developed a detailed measurement framework that will ensure we stay on course:

Positive Impact pillars

Water

We aim to replenish or restore more water, of the same quality or better, than the water withdrawn or consumed in the Nuton process.

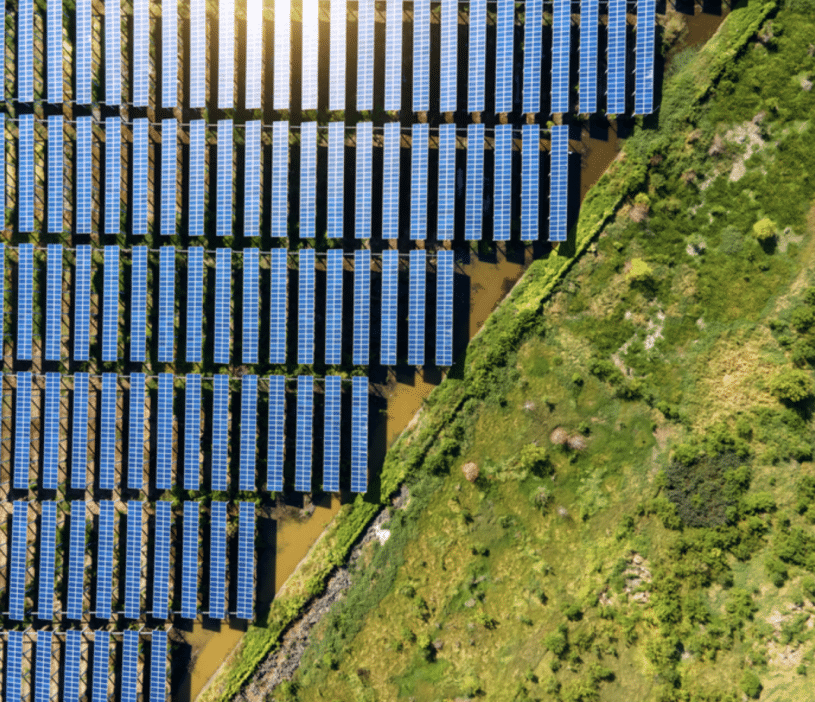

Energy

We aim to support the generation of more renewable energy than the energy Nuton consumes in its process.

Land

We aim to regenerate or repurpose more land, at a greater quality, than the land used during the Nuton process.

Society

We aim to work with local host communities to fulfil self-defined goals leaving them in a better position than before Nuton’s deployment.

Materials

We aim to valorise resources otherwise deemed waste or a liability in larger volumes than the residues produced through the Nuton process.

The value of Nuton’s Positive Impact ambition

Global positive aspirations