Rio Tinto has successfully produced the first copper from the Johnson Camp mine in Arizona using its Nuton® Technology, marking a pivotal step forward in the development of this innovative copper processing technology.

After more than 30 years of research and development, the first copper cathode using Rio Tinto’s proprietary bioleaching technology, which relies on microorganisms grown on site, was produced at Gunnison Copper’s Johnson Camp mine last month. The deployment involves the design and delivery of a technology package for a heap leach pad targeting production of approximately 30,000 tonnes of refined copper over a four-year demonstration period. Rio Tinto is engaging with several potential customers in the U.S. to support the domestic copper supply chain.

Rio Tinto Copper Chief Executive Katie Jackson said, “This is a breakthrough achievement for our Nuton technology, which is proving that cleaner, faster, and more efficient copper production is possible at an industrial scale. In an industry where projects typically take about 18 years to move from concept to production, Nuton has now proven its ability to do this in just 18 months.

“Nuton has designed a modular system deployed as a technology package integrating biology, chemistry, engineering, and digital tools, allowing it to be rapidly scaled and tailored to different ore bodies, unlocking resources that have historically been considered uneconomic or challenging. We are actively partnering on projects in North and South America to assess the potential for future deployment at additional sites in the coming years.”

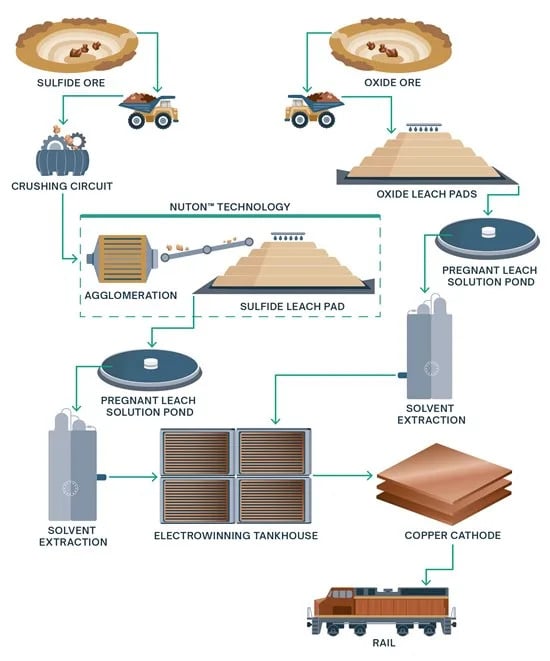

Nuton relies on naturally occurring microorganisms to extract copper from primary sulphide ores, which are traditionally difficult to process. These microbes, grown at large scale in Nuton’s proprietary bioreactors, accelerate the oxidation of minerals in the crushed ore heap, generating heat and enabling copper to dissolve into a leach solution, which is then processed into 99.99% pure copper cathode.

Significantly, processing copper ore with Nuton eliminates the need for concentration, smelting and refining, shortening supply chains and delivering copper cathode at the mine gate. It achieves recovery rates of up to 85% from primary sulphides, the most abundant copper bearing ores in the world.

Nuton can also extend mine life and maximize resource use by extracting value from ores that would otherwise be classified as waste, increasing yield and revenue at both new and existing mines. Its environmental performance is expected to exceed conventional copper processing technologies, with up to 80% less water usage and up to 60% lower carbon emissions than the traditional concentrator route.

At Johnson Camp, Nuton aims to produce copper with the lowest carbon footprint in the U.S. Through the purchase of 134,000 Green-e Energy certified renewable energy certificates, Nuton ensures 100% of the site’s electricity is matched by renewable sources. The copper produced is anticipated to have a mine-to-metal carbon footprint of 0.82-kilogram CO₂-e per kilogram copper, the lowest in the U.S. and substantially lower than the projected 2026 global average of 3.4 kilograms CO₂-e per kilogram among operating copper mines. Additionally, water intensity is anticipated to be 71 litres per kilogram copper, compared to the global average industry estimate of ~130 litres per kilogram of copper production.

Gunnison Copper Chief Executive Officer and President Stephen Twyerould said, “The first production of Nuton copper at Johnson Camp is the culmination of exceptional teamwork between Gunnison Copper and Rio Tinto’s Nuton team. Achieving this level of performance in such a short time frame shows what is possible when innovation, operational excellence, and a shared vision come together. With Nuton copper now entering the U.S. supply chain, this milestone underscores the critical role we can play in strengthening domestic access to cleaner, low-carbon copper.”

While this milestone confirms Nuton’s engineering and operational viability, the next phase will focus on validating long-term technical performance. This includes multi-year testing, independent third-party verification, and internal review by Rio Tinto to ensure consistent recovery rates and environmental performance.

Contacts

Please direct all enquiries to media.enquiries@riotinto.com

| Media Relations, United Kingdom Matthew Klar M +44 7796 630 637 David Outhwaite M +44 7787 597 493 | Media Relations, Australia Matt Chambers M +61 433 525 739 Alyesha Anderson M +61 434 868 118 Rachel Pupazzoni M +61 438 875 469 Bruce Tobin M +61 419 103 454 | Media Relations, Canada Simon Letendre M +1 514 796 4973 Malika Cherry M +1 418 592 7293 Vanessa Damha M +1 514 715 2152 |

| Investor Relations, United Kingdom Rachel Arellano M: +44 7584 609 644 David Ovington M +44 7920 010 978 Laura Brooks M +44 7826 942 797 Weiwei Hu M +44 7825 907 230 | Investor Relations, Australia Tom Gallop M +61 439 353 948 Eddie Gan-Och M +976 95 091 237 | Media Relations, US & Latin America Jesse Riseborough M +1 202 394 9480 |

| Rio Tinto plc 6 St James’s Square London SW1Y 4AD United Kingdom T +44 20 7781 2000 Registered in England No. 719885 | Rio Tinto Limited Level 43, 120 Collins Street Melbourne 3000 Australia T +61 3 9283 3333 Registered in Australia ABN 96 004 458 404 |

VANCOUVER, CANADA (November 24, 2025) – Aldebaran Resources Inc. (“Aldebaran” or the “Company”) (TSX-V: ALDE, OTCQX: ADBRF) is pleased to announce the filing on SEDAR+ of an updated Technical Report and Preliminary Economic Assessment (the “Altar PEA”) on the Altar copper-gold project located in San Juan Province, Argentina, prepared in accordance with National Instrument 43-101 – Standards of Disclosure in Mineral Projects. The Altar PEA has an effective date of September 1, 2025, and was created by SRK Consulting Inc. as lead consultants with Knight Piesold as a subcontractor. The report titled “Preliminary Economic Assessment, Altar Project, San Juan, Argentina” has been filed on the SEDAR+ website at www.sedarplus.ca and will be posted on the Company’s website at www.aldebaranresources.com.

Additionally, the Company announces that Nuton Holdings Ltd., a Rio Tinto venture (“Nuton”), has provided notice of termination of the option to joint venture agreement announced on November 7, 2024, under which Nuton had the right to acquire a 20% interest in the Altar project. Nuton’s decision comes as they are shifting priorities to focus on later-stage projects that could potentially deliver nearer-term production. Despite the termination, Nuton and Aldebaran could still enter a licensing agreement to deploy the Nuton® Technology, proprietary bio-leaching technology, at Altar.

John Black, Chief Executive Officer and Director of Aldebaran, commented: “The PEA demonstrated that the base case concentrator scenario for Altar is a long-life project delivering significant copper, gold, and silver production at attractive cash costs while minimizing upfront capital. With an NPV (8%) of US$2 billion and an IRR of 20.5%, we believe that Altar is an attractive large-scale copper gold project and a very important project for Argentina moving forward. We thank Nuton for their participation in the Altar project and understand that their shift in priorities made continuing with the Altar option agreement challenging. We retain an 80% interest in the project and look forward to advancing it towards a pre-feasibility study with our joint venture partner Sibanye-Stillwater.”

Qualified Person

The scientific and technical data contained in this news release has been reviewed and approved by Dr. Kevin B. Heather, B.Sc. (Hons), M.Sc, Ph.D, FAusIMM, FGS, Chief Geological Officer and director of Aldebaran, who serves as the qualified person (QP) under the definitions of National Instrument 43-101.

ON BEHALF OF THE ALDEBARAN BOARD

(signed) “John Black”

John Black

Chief Executive Officer and Director

Tel: +1 (604) 685-6800

Email: info@aldebaranresources.com

Please click here and subscribe to receive future news releases: https://aldebaranresources.com/contact/subscribe/

For further information, please consult our website at www.aldebaranresources.com or contact:

Ben Cherrington

Manager, Investor Relations

Phone: +1 347 394-2728 or +44 7538 244 208

Email: ben.cherrington@aldebaranresources.com

About Aldebaran Resources Inc.

Aldebaran is a mineral exploration company that was spun out of Regulus Resources Inc. in 2018 and has the same core management team. Aldebaran holds an 80% interest in the Altar copper-gold project in San Juan Province, Argentina. The Altar project hosts multiple porphyry copper-gold deposits with potential for additional discoveries. Altar forms part of a cluster of world-class porphyry copper deposits which includes Los Pelambres (Antofagasta Minerals), El Pachón (Glencore), and Los Azules (McEwen Copper). In November 2024 the Company announced an updated mineral resource estimate for Altar, prepared by Independent Mining Consultants Inc. and based on the drilling completed up to and including the 2023-24 field season (independent technical report prepared by Independent Mining Consultants Inc., Tucson, Arizona, titled “Technical Report, Estimated Mineral Resources, Altar Project, San Juan Province, Argentina”, dated December 31, 2024 – see news release dated November 25, 2024).

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Forward-Looking Statements

This news release contains “forward-looking information” or forward-looking statements” within the meaning of Canadian and United States securities legislation. All statements included herein, other than statements of historical fact, including, without limitation, statements relating to the Altar project as a profitable project for the Company, the scale, throughput, resources, projected production and projected profitability of the Altar project, completion of a pre-feasibility study, and projected economics, including NPV, IRR, and cash costs, are forward-looking. Generally, the forward-looking information and forward looking statements can be identified by the use of forward looking terminology such as “plans”, “expects” or “does not expect”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates” or “does not anticipate”, “will continue” or “believes”, or variations of such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “might” or “will be taken”, “occur” or “be achieved”. The material factors or assumptions used to develop forward looking information or statements are disclosed throughout this news release.

Forward looking information and forward-looking statements, while based on management’s best estimates and assumptions, are subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of Aldebaran to be materially different from those expressed or implied by such forward-looking information or forward-looking statements. Although Aldebaran has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information and forward-looking statements, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such information or statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such information or statements. The Company has and continues to disclose in its Management’s Discussion and Analysis and other publicly filed documents, changes to material factors or assumptions underlying the forward-looking information and forward-looking statements and to the validity of the information, in the period the changes occur. The forward-looking statements and forward-looking information are made as of the date hereof and Aldebaran disclaims any obligation to update any such factors or to publicly announce the result of any revisions to any of the forward-looking statements or forward-looking information contained herein to reflect future results. Accordingly, readers should not place undue reliance on forward-looking statements and information.

The mining world just recognized a radical shift in copper production. Nuton earned Mining Magazine‘s 2025 Technology & Innovation Award, validating its pioneering bioleaching process and its immediate, positive impact on the copper sector’s environmental profile.

The award acknowledges Nuton’s superior performance, rapid on-site deployment, and advanced bioleaching technology. The award judges declare, “In a world of falling grades, a process that can make copper sulphides economically attractive is a massive achievement.”

In celebration of the Mining Award for Technology & Innovation award, Nuton CEO Adam Burley sat down with Mining Magazine’s Dominic Hale to discuss the evolution of copper production. Watch the full conversation below.

The annual Mining Magazine Awards recognize outstanding achievements, projects and technologies. They cover various categories such as Mineral Processing, Drill & Blast, Bulk Handling and Net Zero Achievement, honoring companies and individuals for their innovation, efficiency and safety advancements.

VANCOUVER, CANADA (October 30, 2025) – Aldebaran Resources Inc. (“Aldebaran” or the “Company”) (TSX-V: ALDE, OTCQX: ADBRF) is pleased to announce the results of a Preliminary Economic Assessment (“PEA”), prepared in accordance with National Instrument 43-101 standards, for the Altar copper-gold project located in San Juan, Argentina. The base case scenario utilizes a 60,000 tonnes per day (“tpd”) concentrator, processing mineralized material from both open pit and underground sources. The results of the PEA are reported on a 100% basis, while Aldebaran owns an 80% interest in the project, with the remaining 20% held by Sibanye-Stillwater Ltd.

All dollar amounts referenced herein are in US dollars unless otherwise noted.

HIGHLIGHTS

Long life operation with significant production:

- 48-year mine life, including 3 years of construction

- First 20 years1: Average annual production of 121,445 tonnes copper equivalent2 (“CuEq”)

- 108,579 tonnes copper (“Cu”), 43,199 ounces of gold (“Au”), and 570,217 ounces of silver (“Ag”)

- First 30 years1: Average annual production of 116,294 tonnes CuEq

- 105,897 tonnes Cu, 33,866 ounces of Au, and 557,239 ounces of Ag

- LOM: Average annual production of 101,413 tonnes CuEq

- 92,891 tonnes Cu, 27,020 ounces of Au, and 525,192 ounces of Ag

Robust economics with leverage to commodity prices:

- Using base-case metal prices of $4.35/lb Cu, $2,500/oz Au, and $27/oz Ag, the project has an after-tax NPV (8%) of $2.0 billion, an IRR of 20.5% and a payback period of 4 years

- Total LOM gross revenue of $44.7 billion (before TC/RCs, payabilities and transport) and total LOM free cash flow of $10.7 billion

- Using spot prices of $5.00/lb Cu, $3,963/oz Au, and $47/oz Ag, the project has an after-tax NPV (8%) of $3.34 billion and an IRR of 28.0%4

Attractive capital intensity:

- Initial capex for the project is $1.59 billion

- Upfront capital is minimized by taking a staged approach to the tailings storage facility and underground construction

- Capital intensity of $15,713/t of average annual CuEq metal produced3

- NPV @ 8% / Initial Capex ratio of 1.27x

Competitive cost profile:

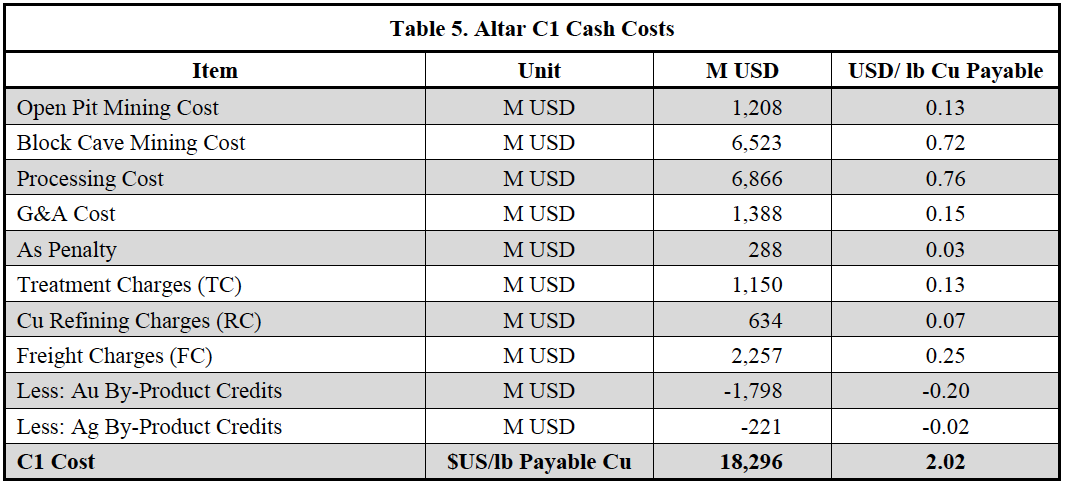

- Cash Costs (C1) of $1.71/lb payable Cu for the first 20 years1, $1.87/lb payable Cu for the first 30 years1, and $2.02/lb payable Cu for the LOM

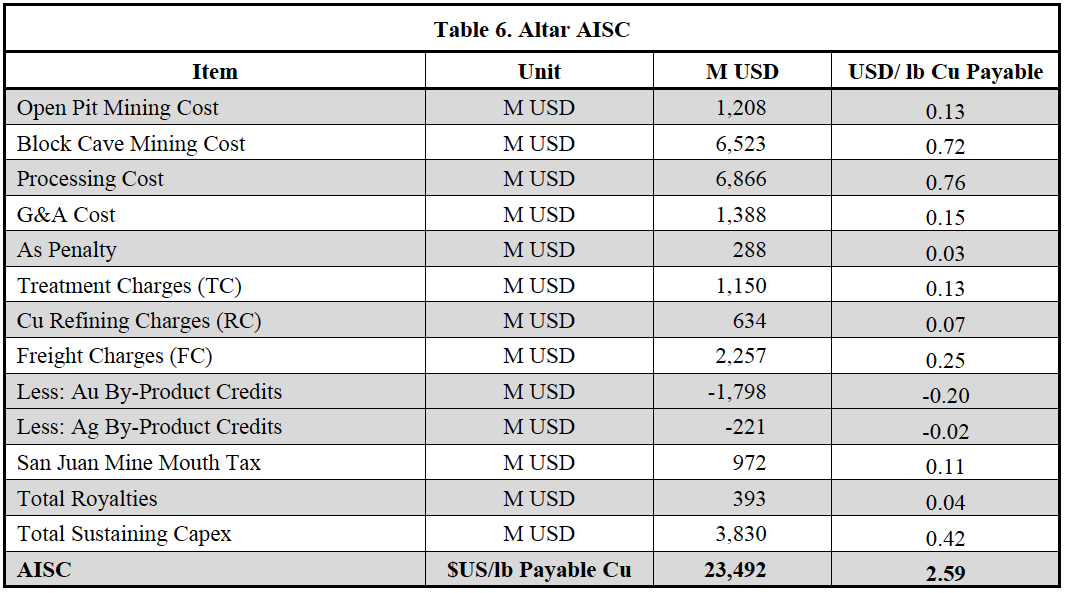

- All in Sustaining Costs (“AISC”) of $2.25/lb payable Cu for the first 20 years1, $2.42/lb payable Cu for the first 30 years1, and $2.59/lb payable Cu for the LOM

Combined Open Pit and Underground Operation:

- Production from the open pit pays back the initial capital, while development of the underground is ongoing

- Underground mining pulls forward better grade mineralization earlier in the mine life, to increase production and generate cash flow

- ~80% of the resources (by tonnage) in the mine plan are categorized as Measured and Indicated, with the remaining ~20% categorized as Inferred

John Black, Chief Executive Officer of Aldebaran, commented: “This PEA confirms that the Altar project has the potential to become a long-life, high-quality copper operation capable of generating substantial production and cash flow. Our objective was to define a mine plan that delivers a minimum of 100,000 tonnes of CuEq per year, while maintaining a compact operational footprint and a disciplined approach to capital. The results of this study clearly achieve those objectives and demonstrate that Altar is a technically and economically robust project. This PEA represents a major milestone for the Company and provides the foundation for our upcoming application for inclusion under Argentina’s RIGI investment framework. With the political environment in Argentina shifting toward pro-business and pro-development policies—as underscored by the recent mid-term election results—the timing for advancing a project of Altar’s scale could not be better. The country is positioning itself to emerge as a significant copper producer at a time when global demand for the metal continues to rise. In addition to the base case concentrator scenario, our collaboration with Nuton, a Rio Tinto venture, demonstrates Nuton® Technology as a potentially viable processing alternative at Altar. Utilizing Nuton® Technology, life-of-mine capital expenditure and operating costs were reduced, leading to higher life-of-mine free cash flow. When you combine the economic results with the ESG benefits of Nuton’s sulphide leaching technology, the Nuton case is quite compelling and warrants further evaluation. The next 12 to 18 months will be transformative for the Company, with multiple key catalysts—including a resource update, completion of the PFS, and the proposed Centauri Minerals spin-out—positioning us to unlock significant value for our shareholders.”

Kevin B. Heather, Chief Geological Officer of Aldebaran, commented: “The PEA represents a significant milestone for the Altar project. In addition to achieving the goals John stated above, we were also focused on maximizing NPV and IRR, hence we elected to move forward with a mine plan that included a combination of open-pit and underground block caving. The block cave, commencing production after the open pit pays back the initial capital, allows us to pull forward higher-grade material in the mine plan and to maintain constant CuEq production numbers, while keeping throughput at 60,000 tpd. Moreover, it keeps the overall footprint of the operation smaller, which is a key consideration for development projects. Our approach to capital expenditures was to stage capital outlays where possible, to ensure initial capital expenditures were kept manageable. Where possible, capital was paid out of cash flow to present a more prudent and attractive development opportunity. We will now begin to shift our focus to the PFS, which will be the next step in de-risking the Altar project. To that end, our 2025/2026 field program is now underway, with most of the work focused on collecting the additional data necessary for the upcoming PFS. This includes additional infill drilling, geotechnical drilling, lab-based geotechnical stress and strain test work, Acid Based Accounting (ABA) test work, environmental monitoring, water wells, water balance studies, community engagement, and more. While this work is ongoing, we will also be exploring several opportunities that we have identified that could potentially unlock additional value from the Altar Project.”

PEA Overview

When available, readers are encouraged to read the PEA in the Company’s technical report (“Technical Report”) prepared in accordance with National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“43-101”) in its entirety, including all qualifications, assumptions and exclusions that relate to the PEA and mineral resource model. The Technical Report is intended to be read as a whole, and sections should not be read or relied upon out of context.

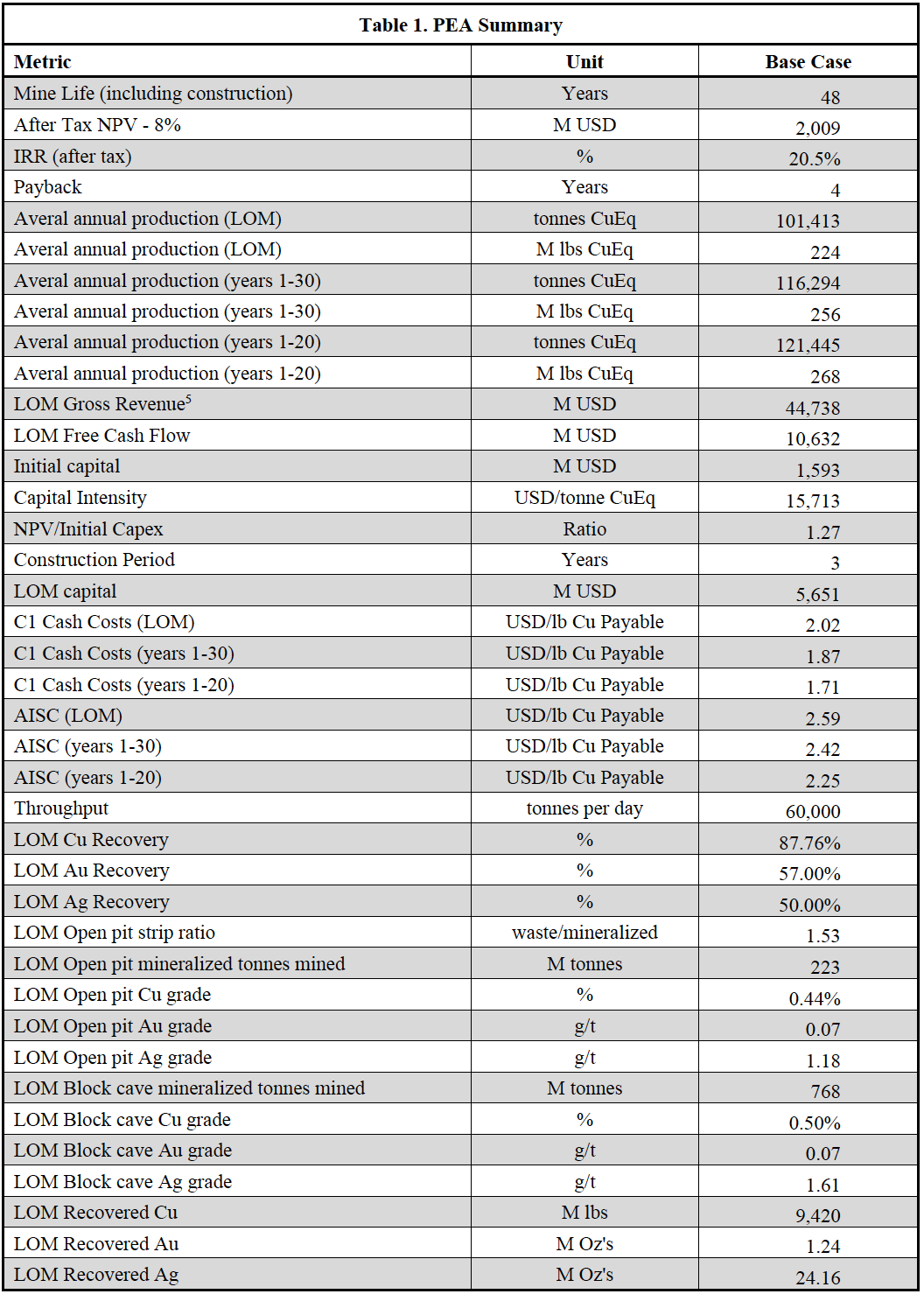

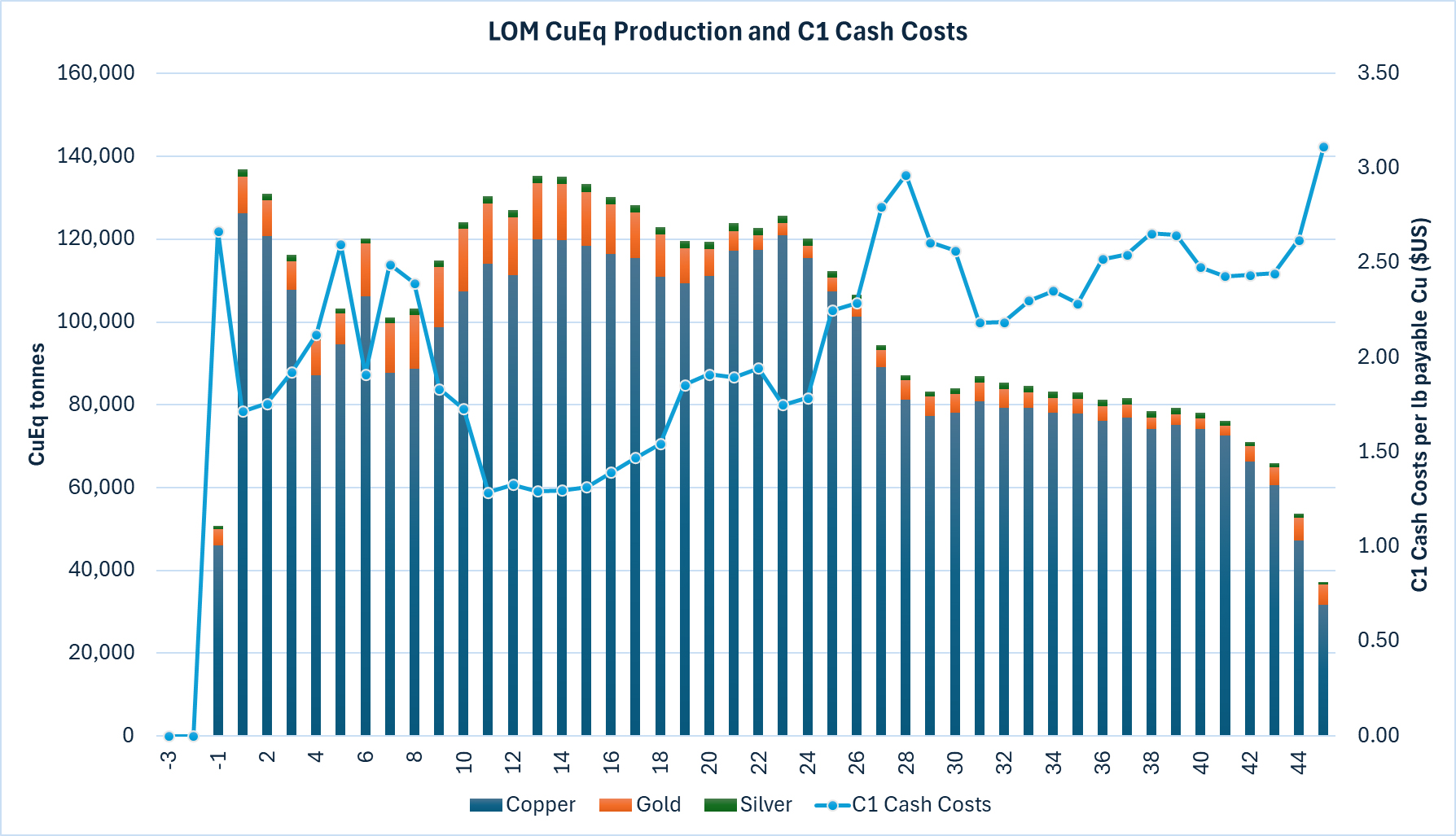

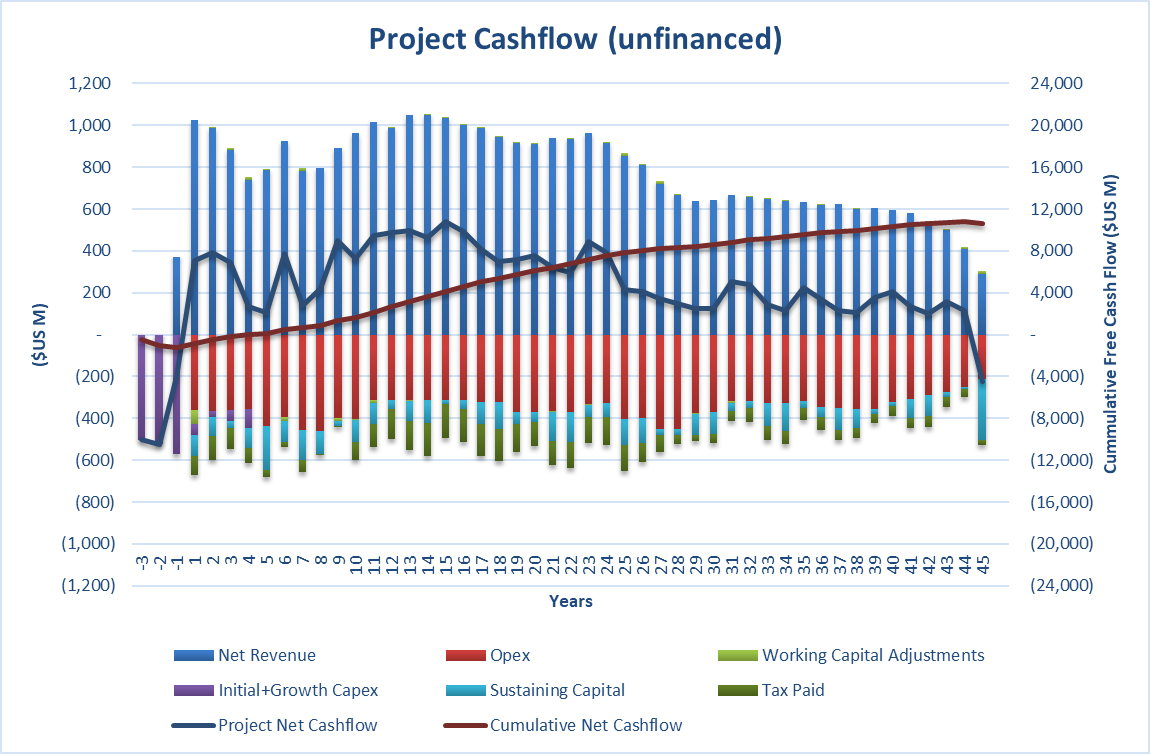

The PEA envisions a combination of open-pit and underground mining, followed by processing via a conventional copper flotation circuit having a nameplate processing capacity of 60,000 tonnes per day. This results in a mine life of 48 years with an average annual production of 102,742 CuEq tonnes for LOM, 116,539 tonnes CuEq for the first 30 years, and 121,748 CuEq tonnes for the first 20 years. Table 1 presents key operating and financial highlights from the PEA, using base study case assumptions of $4.35/lb Cu, $2,500/oz Au and $27/oz Ag. Figure 1 displays annual CuEq production for the LOM, while Figure 2 displays projected cash flows.

Figure 1 – LOM CuEq Production and C1 Cash Costs

Figure 2 – Project Cash Flows

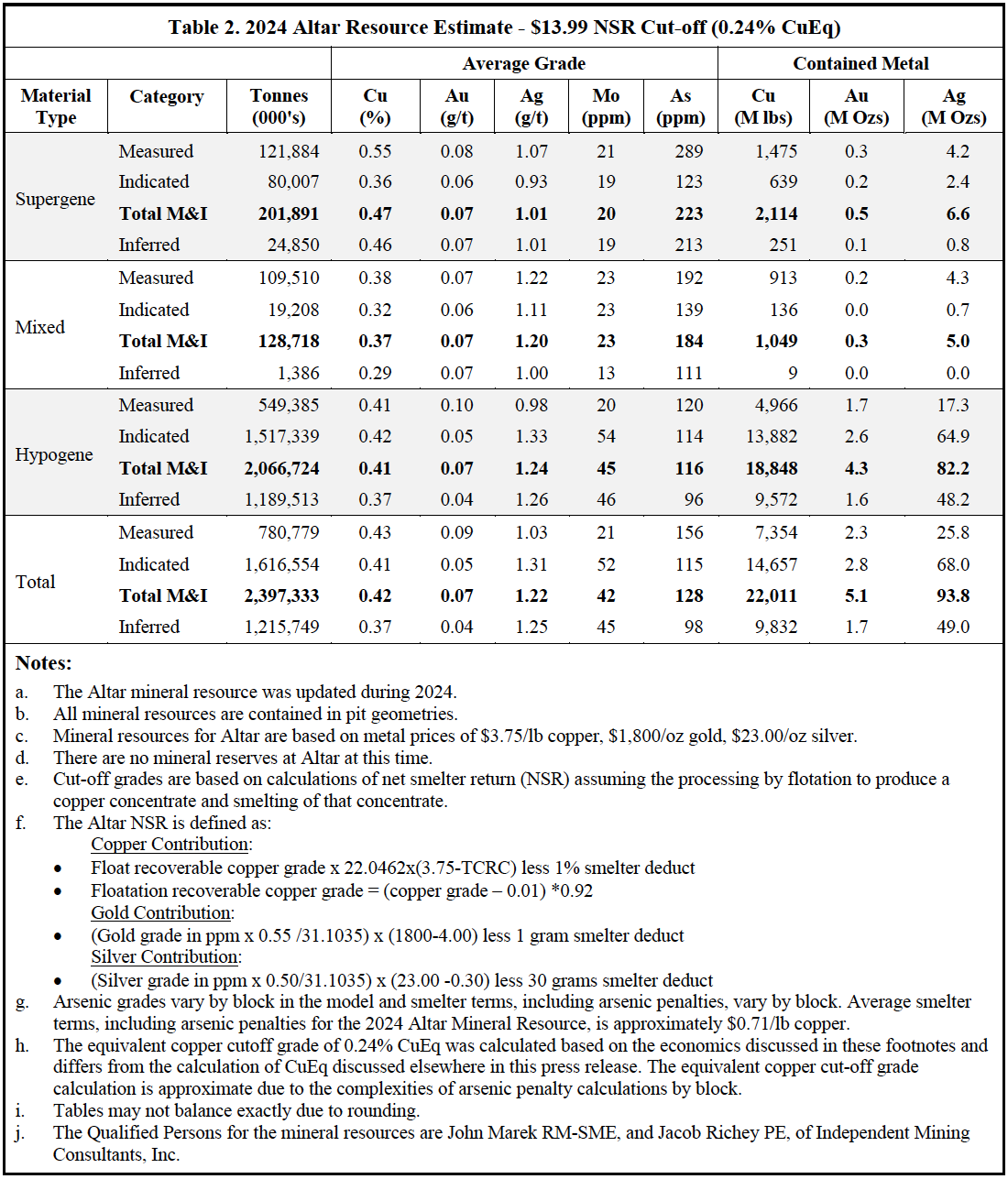

Mineral Resource Estimate

On November 25, 2024, the Company announced an updated mineral resource estimate (“MRE”) for the Altar project (see Table 2). The PEA is based on the MRE; however, the PEA production profile is based on a subset of the MRE, utilizing different metal prices, operating costs, and mining methods.

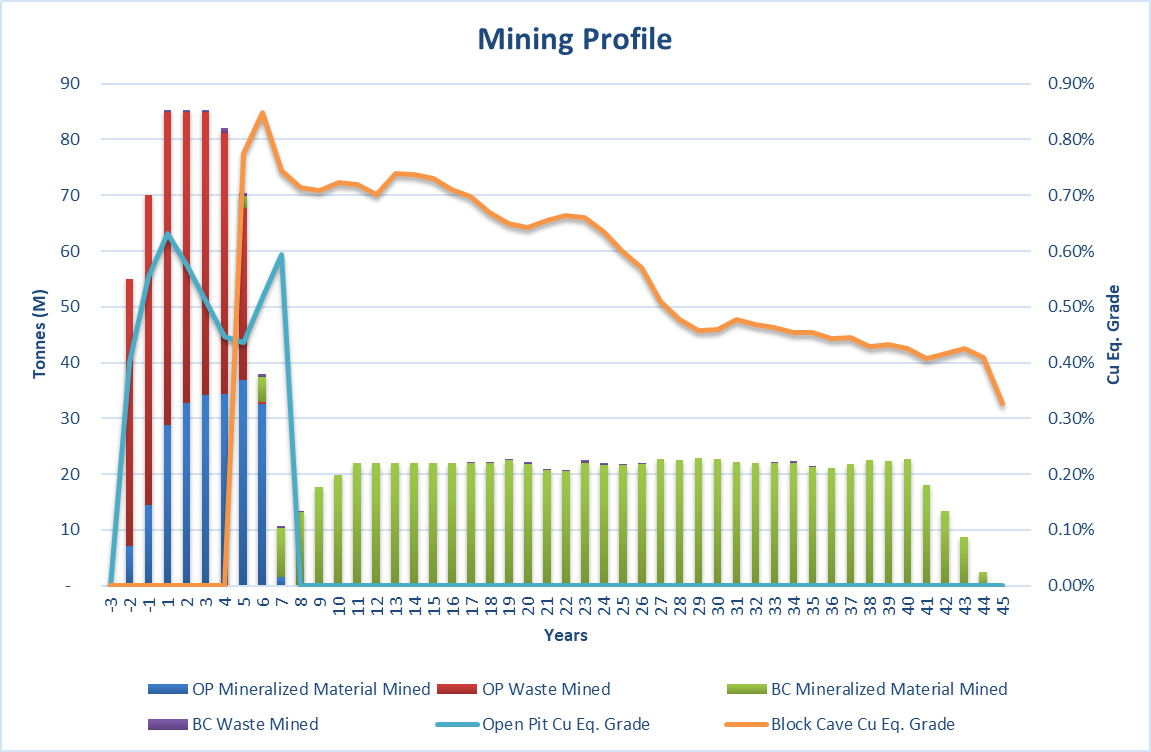

Mining

The proposed mining method is divided into open-pit mining for the near-surface part of the deposit and underground caving for the deeper parts. The open pit will use well-known truck and shovel operations with 12.5-m bench intervals. Haul trucks will be used for hauling mineralized material to the crushing plant and long-term stockpile facilities. Waste rock will be hauled to the closest waste rock storage facility. Underground operations will handle material in bulk using well established block caving methods. Open-pit mining will occur during the first 9 years of operation (in the Altar Central area), while underground development is underway. The mining profile for the project can be seen in Figure 3.

Open pit mining operations will use a smaller-scale equipment fleet that includes 8 m3 hydraulic excavators and 100t capacity SANY haul trucks to allow for narrower bench phases and haul roads, steeper pit slopes, which will facilitate getting into the better-grade, highest-margin mineralization sooner. Underground block cave mining will occur in three areas: Altar East, Altar United, and Altar Central (beneath the open pit). Each underground cave is divided into two lifts, an upper and lower, which will be sequenced as follows: Altar East Upper, Altar United Upper, Altar Central Upper, Altar East Lower, Altar United Lower and Altar Central Lower. Underground access to the block caving mining areas will be through a portal and conveyor drift from the south of the proposed pit (twin declines). To develop the first block cave lift at Altar East, two 3000 m declines are required plus associated development beneath the cave lift.

Figure 3. Mining profile for the LOM

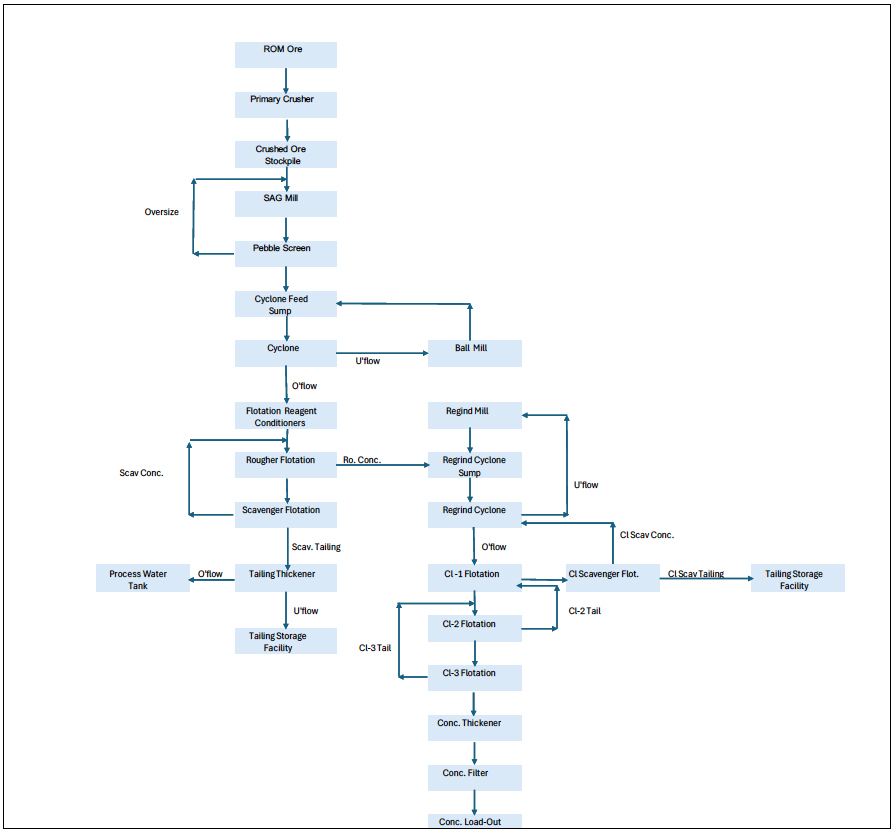

Processing

Extensive metallurgical test work has demonstrated that the contained copper and gold can be effectively recovered in a traditional flotation concentrator that would produce a single gold-bearing copper concentrate using industry-accepted technologies. The flowsheet includes primary crushing followed by grinding in a SAG (semi-autogenous grinding) mill/ball mill grinding circuit, rougher flotation, regrinding of the rougher concentrate and three stages of cleaner flotation. The concentrator would be constructed with a capacity to process 60,000 tpd and operated on a 365 day/year, 24 hour/day schedule. A simplified process flowsheet can be seen in Figure 4. LOM average recoveries for Cu, Au and Ag are 87.76%, 57% and 50% respectively. The grade of the concentrate produced is 26% for the LOM. Arsenic in the concentrate is expected to range from 0.5% to 2.2%. Aldebaran hired the CRU Group, a global leader in commodity research and market analysis, to complete a study analyzing the placement of arsenic-bearing concentrates into the marketplace, which showed that blending capacity for arsenic-bearing copper concentrates worldwide has increased materially in recent years, and penalties paid for arsenic-bearing concentrates have decreased substantially. The PEA utilizes CRU’s view on arsenic penalties.

Figure 4. Processing Circuit

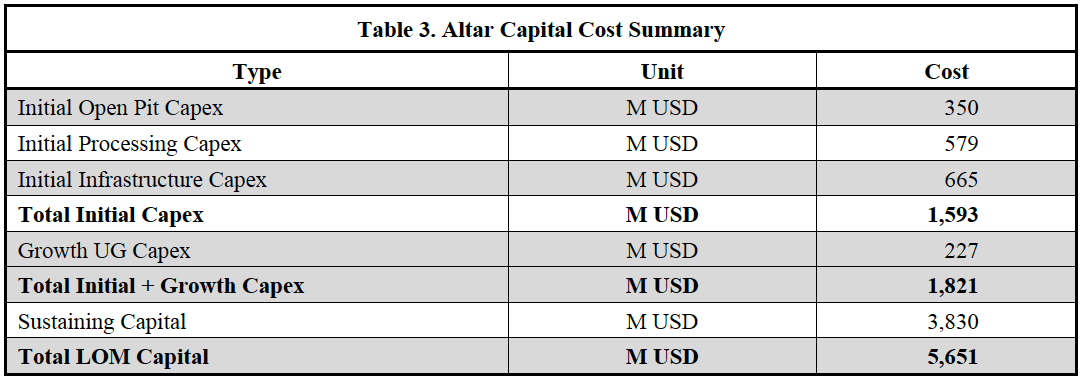

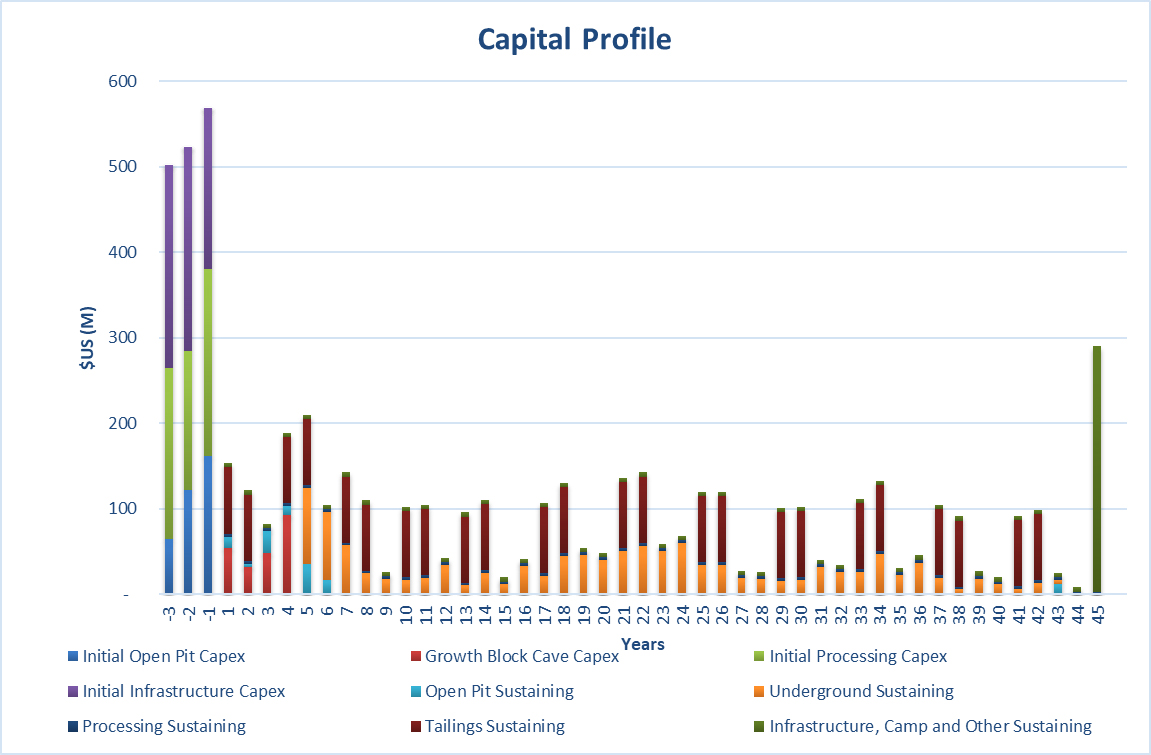

Capital and Operating Costs

The capital cost estimate prepared for the PEA includes an installation cost associated with the site infrastructure, open pit mine and concentrator plant, a growth capital associated with the installation of the block caving underground mining operation, and the sustaining capital associated with the production plan. The LOM summary of capital is presented in Table 3, while the capital profile for the LOM is presented in Figure 5.

Figure 5. Capital Profile for the LOM

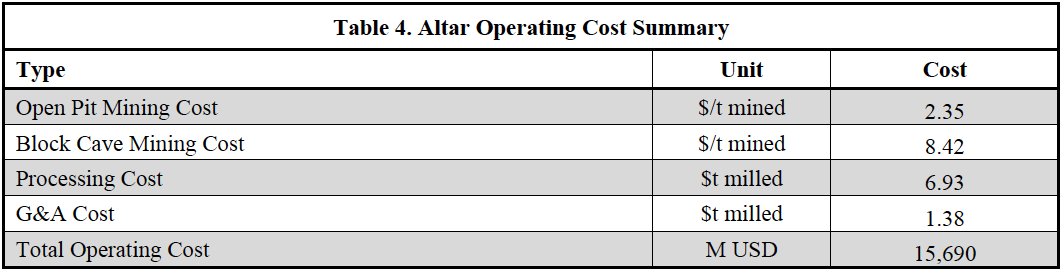

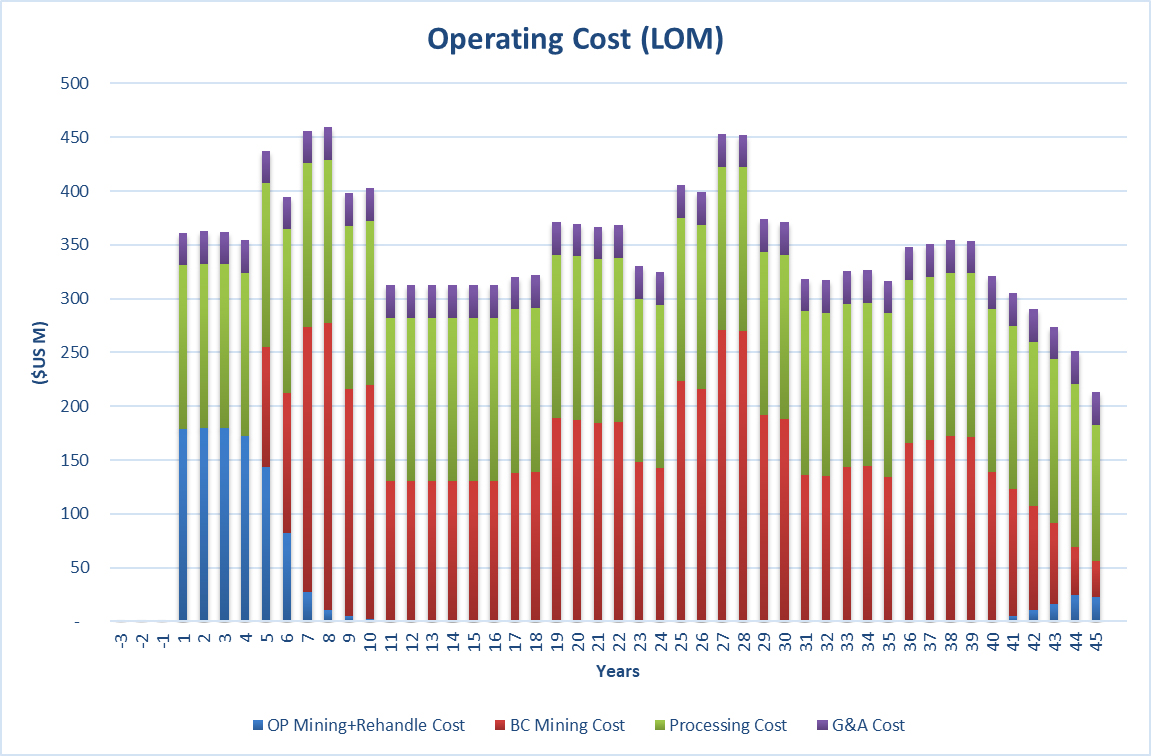

Operating costs were estimated for the open pit mining operation, block caving mining operation, the concentrator processing operation, and G&A. A summary of the estimated operating costs is presented in Table 4. The buildup of LOM C1 cash costs and AISC can be found in Tables 5 and 6, while operating costs by year can be found in Figure 6.

Figure 6. Operating Cost by Year

Infrastructure

The Altar project includes on-site infrastructure such as earthworks development, crushing and process plant facilities as well as ancillary buildings such as camp, warehouses and workshops, on-site roads, water management systems, and site electrical power facilities.

Off-site infrastructure includes a site access road, plant roads, water supply, power supply (power transmission line), two waste rock storage areas, the tailings storage facility, and surface water management structures.

Water use for the project assumes use of surface runoff water, pit dewatering wells, water supply wells within 25 km from the concentrator, with additional water supplied from surface sources.

Nuton, a Rio Tinto venture, Scenario

On November 7, 2024, Aldebaran announced that it had entered an agreement with Nuton Holdings ltd. (“Nuton”), whereby Aldebaran would grant Nuton the option to acquire a 20% stake in the Altar project (see Company press release dated November 7, 2024). As part of that agreement, Aldebaran agreed to include a case in the PEA (“Nuton Case”) utilizing the Nuton® Technology, a suite of proprietary sulphide leaching technologies, as a potential alternative to the base case concentrator scenario reported above (“Base Case”). Nuton® Technology provides the potential to leach both primary and secondary sulphides, providing an alternative processing option for the Altar project. In addition, the Nuton Case provides significant other benefits, such as eliminating the need for a tailings dam, providing a smaller environmental footprint, lower overall energy consumption and lower water consumption than conventional sulphide mineralization treatment processes. Moreover, producing copper cathode on site would eliminate downstream treatment and refining costs, deleterious elements’ penalties, simplify logistics and would provide a finished product at site saleable to the market.

As a result of the work completed in the Phase 1 Nuton® Technology test work program (see Company press release dated November 7, 2024, for details), Nuton has estimated ultimate copper extraction and copper recovery after a 450-day leach cycle for each material type at Altar. The results of this analysis estimate copper extraction from hypogene, mixed and supergene material at 86%, 88% and 91%, respectively. Nuton applies a discount factor of 92% to allow for inherent inefficiencies in the scale up to a commercial heap leach and has, therefore, estimated copper recoveries from hypogene, mixed and supergene material at 79%, 81% and 84%, respectively.

The Nuton Case in the PEA utilizes the same mine plan as the Base Case, due to the use of an overall elevated cutoff grade for both cases; however, it utilizes Nuton® Technology, a bio-leach heap leaching process targeting the leaching of primary and secondary copper sulfide minerals and has been designed to process 60,000 tpd, matching the Base Case throughput. Material will be crushed and processed using a conventional lined heap leach pad and combined with a standard SX/EW facility will produce saleable copper cathode onsite. Aldebaran currently does not have a commercial agreement with Nuton to deploy Nuton® Technology at Altar and there is no guarantee an agreement will come to fruition. For comparative purposes, the Nuton Case does not include project costs associated with licensing and Nuton® Technology services at the Altar Project.

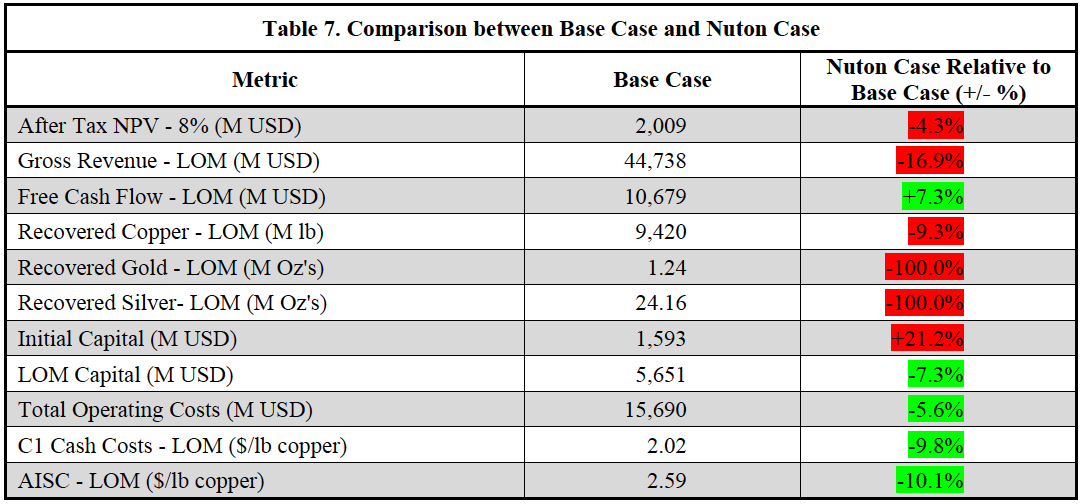

To demonstrate the Nuton Case, the variance percentage relative to the Base Case is included here for selected key production and financial metrics. The results of the Nuton Case can be found in Table 7. Measurable contributors to capital spend include a Tailings Storage Facility (TSF) for the Base Case and a Heap Leach Pad (HLP) for the Nuton Case. The Nuton case shows higher initial capital requirements due to the need for more infrastructure from the start-up (e.g. full-sized ponds) compared to a TSF. However, LOM capex in the Nuton Case is lower, as TSF requires higher sustaining capex to reach final capacity. Additionally, at this time, precious metals such as gold and silver cannot be recovered with Nuton® Technology, whereas they are recovered in the Base Case. Timing of capital and revenue from copper equivalent reduces the NPV for the Nuton Case, but lower total capital and lower operating C1 and AISC costs allow for a higher Free Cash Flow in the Nuton Case.

Green represents metrics where the Nuton case improved over the base case whereas red represents metrics where the base case was more attractive than the Nuton case

Opportunities

Several opportunities to potentially unlock additional value remain to be evaluated, including:

- Installation of a molybdenum circuit in the later years of the mine when higher-grade molybdenum is encountered in the lower block caves

- Additional metallurgy to potentially improve copper recoveries

- Combined concentrator and Nuton® Technology scenario

- Processing of concentrate on-site rather than shipping to a smelter

- Filtered tailings storage

- Producing a pyrite concentrate from the pyrite-rich waste rock, that could be used in the Nuton Case

- Upsizing the daily production rate and copper output with better metal prices

Next Steps

- The 2025/2026 field season is underway, with four drill rigs currently being mobilized to site

- Additional infill drilling to convert inferred resources to the measured and indicated categories

- Preparation to apply for inclusion under Argentina’s RIGI benefits

- Produce an updated mineral resource estimate based on the infill drilling completed in 2024-2025 and the to-be-completed 2025-2026 infill drilling (resource conversion)

- Geotechnical drilling within the PEA open pit and underground block caves

- Geotechnical drilling within the PEA tailings storage facility

- Lab-based geotechnical stress and strain test work

- Acid Based Accounting (ABA) test work

- Drilling additional water wells and conducting additional pump tests for water balance studies

- Continue environmental monitoring studies

Study Notes

Aldebaran retained SRK Consulting Inc. as lead consultants, with Knight Piesold as a subcontractor.

The PEA is preliminary in nature, as it includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the PEA will be realized. Mineral Resources that are not Mineral Reserves and do not have demonstrated economic viability.

Webinar

For more context, please join the Company in a live event on Friday, October 31 at 11:00 am EST / 8:00 am PDT.

Click here to register: https://6ix.com/event/aldebaran-resources-presents-pea-results.

Qualified Person

The scientific and technical data contained in this news release has been reviewed and approved by Dr. Kevin B. Heather, B.Sc. (Hons), M.Sc, Ph.D, FAusIMM, FGS, Chief Geological Officer and director of Aldebaran, who serves as the qualified person (QP) under the definitions of National Instrument 43-101.

Notes

- Assumes commercial production begins in year 1 after 3 years of construction. 20- and 30-year averages calculated starting in year 1.

- CuEq calculated in the PEA study using $4.35/lb Cu, $2,500/oz Au and $27/oz Ag and is reported utilizing recoveries of 87.76% for Cu, 57% for Au, and 50% for Ag.

- Capital intensity calculated as initial capex divided by LOM average annual CuEq production.

- LME copper price, gold and silver price as of market close on October 27, 2025. The NPV calculation using spot prices was not part of the PEA report and was calculated by Aldebaran using the financial model provided by SRK.

- Before TC/RCs, payabilities and transport.

ON BEHALF OF THE ALDEBARAN BOARD

(signed) “John Black”

John Black

Chief Executive Officer and Director

Tel: +1 (604) 685-6800

Email: info@aldebaranresources.com

Please click here and subscribe to receive future news releases: https://aldebaranresources.com/contact/subscribe/

For further information, please consult our website at www.aldebaranresources.com or contact:

Ben Cherrington

Manager, Investor Relations

Phone: +1 347 394-2728 or +44 7538 244 208

Email: ben.cherrington@aldebaranresources.com

About Aldebaran Resources Inc.

Aldebaran is a mineral exploration company that was spun out of Regulus Resources Inc. in 2018 and has the same core management team. Aldebaran holds an 80% interest in the Altar copper-gold project in San Juan Province, Argentina. The Altar project hosts multiple porphyry copper-gold deposits with potential for additional discoveries. Altar forms part of a cluster of world-class porphyry copper deposits which includes Los Pelambres (Antofagasta Minerals), El Pachón (Glencore), and Los Azules (McEwen Copper). In November 2024 the Company announced an updated mineral resource estimate for Altar, prepared by Independent Mining Consultants Inc. and based on the drilling completed up to and including the 2023-24 field season (independent technical report prepared by Independent Mining Consultants Inc., Tucson, Arizona, titled “Technical Report, Estimated Mineral Resources, Altar Project, San Juan Province, Argentina”, dated December 31, 2024 – see news release dated November 25, 2024).

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Forward-Looking Statements

This news release contains “forward-looking information” or forward-looking statements” within the meaning of Canadian and United States securities legislation. All statements included herein, other than statements of historical fact, including, without limitation, statements relating to the Altar project as a profitable project for the Company, the scale, throughput, resources, projected production and projected profitability of the Altar project, timeline for the completion of a mineral resource update, a pre-feasibility study, and the proposed spin-out of Centauri Minerals, projected gold prices and other assumptions, projected economics, including NPV, IRR, cash costs, AISC and payback period, are forward-looking. Generally, the forward-looking information and forward looking statements can be identified by the use of forward looking terminology such as “plans”, “expects” or “does not expect”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates” or “does not anticipate”, “will continue” or “believes”, or variations of such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “might” or “will be taken”, “occur” or “be achieved”. The material factors or assumptions used to develop forward looking information or statements are disclosed throughout this news release.

Forward looking information and forward looking statements, while based on management’s best estimates and assumptions, are subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of Aldebaran to be materially different from those expressed or implied by such forward-looking information or forward looking statements. Although Aldebaran has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information and forward-looking statements, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such information or statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such information or statements. The Company has and continues to disclose in its Management’s Discussion and Analysis and other publicly filed documents, changes to material factors or assumptions underlying the forward-looking information and forward-looking statements and to the validity of the information, in the period the changes occur. The forward-looking statements and forward-looking information are made as of the date hereof and Aldebaran disclaims any obligation to update any such factors or to publicly announce the result of any revisions to any of the forward-looking statements or forward-looking information contained herein to reflect future results. Accordingly, readers should not place undue reliance on forward-looking statements and information.

From vaccines to copper: a biologist’s unlikely journey into mining

Peter Lavrencic owns a front-row seat to mining history in the making. As Nuton heads towards producing first copper at Gunnison Copper Corp.’s Johnson Camp Mine in Arizona, Peter, Nuton’s Biotechnology Lead, plays a key role in the biological process behind a major milestone: the first industrial-scale demonstration of the proprietary Nuton® Technology.

With first Nuton Copper expected in late 2025, this moment marks a turning point for the venture—validating the Nuton Technology’s proprietary process at scale and paving the way for commercial deployment and a new era in sustainable copper production.

A biochemist’s path to bioleaching

Peter says he’s had an untraditional career path crossing from pharmaceuticals to mining. “It’s incredible how you can transfer your knowledge across what seem like unrelated industries.” He previously worked in the manufacturing, development, and regulatory affairs of vaccines and biological medicines in the pharmaceutical industry. As an ever-curious biochemist and biologist, Peter was so drawn to Nuton’s breakthrough in environmentally conscious copper mining technology that he swapped his career in pharma for one in cutting-edge copper.

Today, Peter’s work bridges the fields of biology and mining. Instead of growing biological medicines in bioreactors for pharmaceuticals, he’s applying similar science to bioleaching in the mining sector. “Mining has historically been seen as a ‘polluting and non-environmentally friendly’ industry, but this new biological process of bioleaching is a positive shift toward a cleaner, more sustainable method whilst delivering a critical resource for our society.”

Microbes that mine: the science behind the heap

Nuton’s approach to copper mining is game-changing. “Our process is more cost-effective and better for the environment compared to traditional methods mining this ore type.” Moving away from traditional, high-energy-use methods, the Nuton® Technology employs a proprietary biological process using specially curated microorganisms to extract copper from ore.

Massive bioreactors serve as breeding grounds where Nuton’s microbes are born to mine. The facility encompassing the bioreactors – the BIGF for short – is the star bioreactor at Johnson Camp Mine where the microbial magic happens.

“It’s like a maternity ward of microbes, where we provide the incentive and conditions to multiply the right microbes at a maximal rate,” Peter says. These microbes work by “eating” ore components such as iron in the ore, which through a series of chemical reactions releases copper in a process that’s as fascinating as it is revolutionary.

“In the pharmaceutical industry, we grow cells and use their components for the medicine. What we’re doing in mining is somewhat similar. We’ve designed a special composition of microbes to grow in large bioreactors and the cells themselves are the ‘medicine’ for our heap.”

Scaling up sustainably

Peter’s focus is on optimizing the biological side of the process – ensuring the right diversity of microbes is fine-tuned to perform reliably at scale. This is no small feat: the microbes must thrive in harsh mining environments, adapt to changing conditions, and work together in complex chemical reactions.

“People have been mining copper for centuries. Much of the easy-to-mine copper has been mined out. Additionally, the world is more conscious of the environment.” Peter proudly adds that the Nuton Technology isn’t just about producing copper – it’s about doing it more sustainably. These microbes consume carbon dioxide as they work, and water is continuously recycled — turning mining’s biggest environmental challenges into solutions.

Johnson Camp: a launchpad for the future of copper mining

When Peter joined Nuton, everything was still on paper for JCM. Today, Johnson Camp Mine is a buzzing launching pad, with key infrastructure connected and ready for commissioning – the final step before copper production begins.

For him, the biggest reward of the project has been seeing it come off the paper into real life, and the collaboration taking place across Nuton’s team to make this a reality. From mining engineers and metallurgists to AI specialists, the Johnson Camp journey has been powered by a diverse group of experts to bring the Nuton Technology to life.

The learnings and successes from Johnson Camp will inform future deployments across other copper-rich regions, from Arizona to South America.

“I’m a scientist, so new things excite me. I can genuinely use my skills in a unique way.” Peter is thrilled to witness years of biological development come to life at Johnson Camp Mine. In an industry that’s remained largely unchanged for centuries, copper mining is now being revolutionized by the power of biology.

America’s Newest Copper Producer Delivers Ahead of Schedule

Phoenix, Arizona–(Newsfile Corp. – September 3, 2025) – Gunnison Copper Corp. (TSX: GCU) (OTCQB: GCUMF) (FSE: 3XS0) (“Gunnison” or the “Company”) is thrilled to announce the first production of pure copper cathode from its fully-operational Johnson Camp Mine (“JCM”) in southeast Arizona commenced in the last week of August 2025, establishing Gunnison as the newest American Copper Producer.

Following the successful start-up of the solvent extraction (SX) and electrowinning (EW) circuit (announced August 11, 2025), copper cathode is now officially in production from run-of-mine (ROM) ore. Gunnison has achieved this critical milestone ahead of schedule, producing Made-in-America copper for domestic sales.

“This is an incredible moment for Gunnison and for U.S. copper supply. To bring Johnson Camp into production ahead of schedule and with an excellent health and safety record is an achievement we’re extremely proud of,” states Stephen Twyerould, Chief Executive Officer and President. “Even more exciting is that we are now producing 100% American-made copper at a time when our nation needs it most. We extend our gratitude to our dedicated team, valued stakeholders, and especially Nuton LLC, a Rio Tinto venture, whose critical support made this possible.”

Nuton is a key strategic and financial partner to Gunnison, supporting the restart of copper production at JCM. With exclusive rights to deploy its proprietary leaching technologies, Nuton is enabling a more sustainable and economically viable path for copper recovery at JCM.

“We congratulate Gunnison Copper and its dedicated team on this important milestone and are proud to support the company’s efforts in revitalizing mining in Arizona,” added Adam Burley, Nuton’s Chief Executive Officer. “We look forward to first copper production using Nuton technologies later this year, unlocking copper through innovation and partnership.”

Key Highlights of the Johnson Camp Mine Commissioning:

- First copper production achieved ahead of schedule, firmly establishing Gunnison as America’s newest copper producer.

- Exceptional safety performance: Commissioning of the ROM copper production circuit completed without incident, underscoring Gunnison’s uncompromising commitment to health and safety excellence.

- Critical U.S. supply: New domestic production strengthens American energy independence, national defense, and advanced manufacturing capabilities.

- Partnerships: Fully funded and supported by Nuton LLC, a Rio Tinto venture, and awarded US$13.9 million in 48C tax credits from the Department of Energy (see Gunnison press release dated January 16, 2025 for additional details).

- Growth trajectory: Ramp-up in progress toward the name plate plant capacity of 25 million pounds of finished copper cathode annually.

ABOUT GUNNISON COPPER

Gunnison Copper Corp. is a multi-asset pure-play copper developer and producer that controls the Cochise Mining District (the district), containing 12 known deposits within an 8 km economic radius, in the Southern Arizona Copper Belt.

Its flagship asset, the Gunnison Copper Project, has a Measured and Indicated Mineral Resource containing over 831.6 million tons with a total copper grade of 0.31% (Measured Mineral Resource of 191.3 million tons at 0.37% and Indicated Mineral Resource of 640.2 million tons at 0.29%), and a preliminary economic assessment (“PEA“) yielding robust economics including an NPV8% of $1.3 Billion, IRR of 20.9%, and payback period of 4.1 years. It is being developed as a conventional operation with open pit mining, heap leach, and SX/EW refinery to produce finished copper cathode on-site with direct rail link.

The PEA is preliminary in nature and includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. There is no certainty that the conclusions reached in the PEA will be realized. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

In addition, Gunnison’s Johnson Camp Asset, which is now in production, is fully funded by Nuton LLC, a Rio Tinto Venture, with a production capacity of up to 25 million lbs of finished copper cathode annually.

Other significant deposits controlled by Gunnison in the district, with potential to be economic satellite feeder deposits for Gunnison Project infrastructure, include Strong and Harris, South Star, and eight other deposits.

For additional information on the Gunnison Project, including the PEA and mineral resource estimate, please refer to the Company’s technical report entitled “Gunnison Project NI 43-101 Technical Report Preliminary Economic Assessment” dated effective November 1, 2024 and available on SEDAR+ at www.sedarplus.ca.

Dr. Stephen Twyerould, Fellow of AUSIMM, President and CEO of the Company is a Qualified Person as defined by NI 43-101. Dr. Twyerould has reviewed and is responsible for the technical information contained in this news release.

For more information on Gunnison, please visit our website at www.GunnisonCopper.com.

ABOUT NUTON

Nuton is an innovative venture that aims to help grow Rio Tinto’s copper business. At the core of Nuton is a portfolio of proprietary copper leaching technologies and capability. Nuton has the potential to economically unlock copper from hard-to-leach ores, including primary sulfides and, in doing so, increase domestic production of critical minerals to support the energy transition. Nuton technologies can achieve market-leading recovery rates and boost copper production in new, ongoing and historical operations, increasing resource utilization and maximizing value.

With significantly lower energy and water needs than conventional concentrating and smelting, and the ability to produce copper cathode at the mine site, Nuton offers a reliable source of domestically produced copper, with a short mine-to-metal supply chain and the ambition to set industry-leading ESG credentials.

One of the key differentiators of Nuton is the ambition to produce the world’s lightest environmental footprint copper while having at least one Positive Impact at each of its deployment sites, across its five pillars: water, energy, land, materials and society.

For more information, please visit https://nuton.tech.

For further information regarding this press release, please contact:

Gunnison Copper Corp.

Concord Place, Suite 300, 2999 North 44th Street, Phoenix, AZ, 85018

Melissa Mackie

T: 647.533.4536

E: info@GunnisonCopper.com

www.GunnisonCopper.com

Cautionary Note Regarding Forward-Looking Information

This news release contains “forward-looking information” concerning anticipated developments and events that may occur in the future. Forward-looking information contained in this news release includes, but is not limited to, statements with respect to: (i) the intention to deploy the Nuton® technology at the Johnson Camp mine and future production therefrom; (ii) the continued funding of the stage 2 work program by Nuton; (iii) the details and expected results of the stage two work program; (iv) timelines for future production and production capacity from the Company’s mineral projects; (v) expectations regarding the timing and amount of 48C tax credits; (vi) the results of the preliminary economic assessment on the Gunnison Project; and (vIi) the exploration and development of the Company’s mineral projects.

In certain cases, forward-looking information can be identified by the use of words such as “plans”, “expects” or “does not expect”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates” or “does not anticipate”, or “believes”, or variations of such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “might”, “occur” or “be achieved” suggesting future outcomes, or other expectations, beliefs, plans, objectives, assumptions, intentions or statements about future events or performance. Forward-looking information contained in this news release is based on certain factors and assumptions regarding, among other things, Nuton will continue to fund the stage 2 work program, the availability of financing to continue as a going concern and implement the Company’s operational plans, the estimation of mineral resources, the realization of resource and reserve estimates, , copper and other metal prices, the timing and amount of future development expenditures, the estimation of initial and sustaining capital requirements, the estimation of labour and operating costs (including the price of acid), the availability of labour, material and acid supply, receipt of and compliance with necessary regulatory approvals and permits, the estimation of insurance coverage, and assumptions with respect to currency fluctuations, environmental risks, title disputes or claims, and other similar matters. While the Company considers these assumptions to be reasonable based on information currently available to it, they may prove to be incorrect.

Forward-looking information involves known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements of the Company to be materially different from any future results, performance or achievements expressed or implied by the forward-looking information. Such factors include risks related to the Company not obtaining adequate financing to continue operations, Nuton failing to continue to fund the stage 2 work program, the breach of debt covenants, risks inherent in the construction and operation of mineral deposits, including risks relating to changes in project parameters as plans continue to be redefined including the possibility that mining operations may not be sustained at the Gunnison Copper Project, risks related to the delay in approval of work plans, variations in mineral resources and reserves, grade or recovery rates, risks relating to the ability to access infrastructure, risks relating to changes in copper and other commodity prices and the worldwide demand for and supply of copper and related products, risks related to increased competition in the market for copper and related products, risks related to current global financial conditions, risks related to current global financial conditions on the Company’s business, uncertainties inherent in the estimation of mineral resources, access and supply risks, risks related to the ability to access acid supply on commercially reasonable terms, reliance on key personnel, operational risks inherent in the conduct of mining activities, including the risk of accidents, labour disputes, increases in capital and operating costs and the risk of delays or increased costs that might be encountered during the construction or mining process, regulatory risks including the risk that permits may not be obtained in a timely fashion or at all, financing, capitalization and liquidity risks, risks related to disputes concerning property titles and interests, environmental risks and the additional risks identified in the “Risk Factors” section of the Company’s reports and filings with applicable Canadian securities regulators.

Although the Company has attempted to identify important factors that could cause actual actions, events or results to differ materially from those described in forward-looking information, there may be other factors that cause actions, events or results not to be as anticipated, estimated or intended. Accordingly, readers should not place undue reliance on forward-looking information. The forward-looking information is made as of the date of this news release. Except as required by applicable securities laws, the Company does not undertake any obligation to publicly update or revise any forward-looking information.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/264914

Base Case $4.30/lb copper, Post-Tax NPV (7%) $694 million and 14.6% IRR with payback at 6.7 years

Advancing Clear Path to Near-Term Production of U.S. Refined Copper Cathode

Yerington, Nevada–(Newsfile Corp. – August 5, 2025) – Lion Copper and Gold Corp. (CSE: LEO) (OTCQB: LCGMF) (“Lion Copper and Gold” or the “Company“) is pleased to announce the results of the Pre-Feasibility Study (PFS) for its wholly-owned Yerington Copper Project, located in Lyon County, Nevada. The PFS, completed pursuant to the provisions of National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”), demonstrates and confirms the Project’s potential as a significant refined copper cathode producer in the United States in the heart of the Yerington Copper District. The PFS was prepared by Samuel Engineering Inc., with input from independent Qualified Persons (QPs), and was fully funded by the Company’s strategic partner, Nuton LLC, a Rio Tinto venture.

In this news release, all dollar amounts are in United States dollars (“$”) and imperial units are utilized.

Highlights

Sizeable and scalable open pit heap leach project

- Average annual production of 120 million pounds of refined copper cathode over a 12-year mine life, with a peak of 151 million pounds in Years 5-7.

- Proven and Probable Reserves of 506.5 million tons at 0.21% CuT, containing 2.14 billion pounds of copper.

- Excluding reserves, an additional Measured & Indicated Resource of 293.3 million tons at 0.18% CuT, containing 989 million pounds of copper and an additional Inferred Resource of 158.1 million tons at 0.14% CuT, containing 443.4 million pounds of copper.

- Strong copper recovery performance with an average of 67.4% LOM copper recovery from low-cost heap leaching – 73.2% copper recovery from sulfides using Nuton leach technology and 60% from oxides in a conventional heap leach.

- Extensive land holdings include patented and unpatented mining claims as well as private land adjacent to other significant copper deposits.

- The Project plans to spend approximately $70M to treat 43,000 acre-feet of Yerington Pit Lake water and release this water to the environment for multiple beneficial stakeholder uses in the Mason Valley.

- Benefits of the Project include utilizing disturbed land for mine infrastructure, zero discharge of water from copper processing operations, lower carbon intensity, and efficiently delivering copper cathode directly into U.S. supply chains.

John Banning, CEO of the Company, states, “With growing domestic demand for refined copper, we are pleased to announce the completion of the Pre-Feasibility Study for our Yerington Copper Project, a brownfield asset in Nevada, planned to produce 120 million pounds of refined copper cathode annually over a 12-year mine life. This PFS showcases Lion Copper and Gold’s strategic advantage in the Yerington Copper District, bolstered by secured water rights, the Bear Deposit’s significant potential, strategic land control, and proximity to major neighboring copper projects, positioning us to deliver significant shareholder value and strengthen North America’s critical minerals supply chain.”

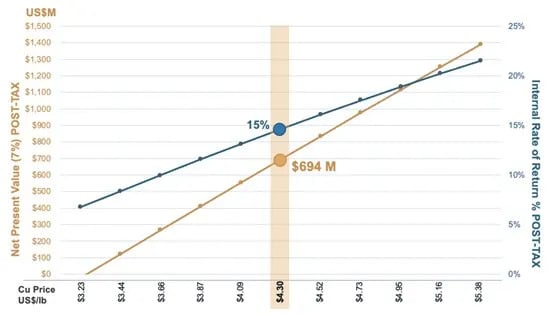

Economics

- Base Case $4.30/lb copper, Post-Tax NPV (7%) $694 million and 14.6% IRR with payback at 6.7 years.

- Initial Capital: $724 million, including mine development, heap leach pads, SX/EW plant, acid plant and related infrastructure.

- Base Case NPV-to-Initial Capital Ratio of 0.96.

- Operating Costs: Cash cost (C1)1 of $1.92 per pound of copper.

- All-in Sustaining Costs (AISC)1 of $2.67 per pound of copper.

- Base Case Capital Intensity* of $12,044/tpa.

* Initial capital expenditures divided by average annual copper production for mine life

Copper Price Sensitivity

| Sensitivity | Copper Price | Pre-Tax | Post-Tax | ||||

| (%) /item | Cu/lb | NPV(7%) | IRR | Payback | NPV(7%) | IRR | Payback |

| $M | % | Years | $M | % | Years | ||

| -25% | $3.23 | $111 | 8% | 8.9 | ($21) | 7% | N/A |

| -20% | $3.44 | $284 | 10% | 8.2 | $122 | 8% | 8.6 |

| -15% | $3.66 | $457 | 12% | 7.6 | $266 | 10% | 7.9 |

| -10% | $3.87 | $629 | 14% | 7.1 | $410 | 12% | 7.4 |

| -5% | $4.09 | $802 | 15% | 6.7 | $553 | 13% | 7.0 |

| Base Case | $4.30 | $975 | 17% | 6.4 | $694 | 15% | 6.7 |

| 5% | $4.52 | $1,148 | 19% | 6.1 | $836 | 16% | 6.4 |

| 10% | $4.73 | $1,321 | 20% | 5.8 | $976 | 18% | 6.1 |

| 15% | $4.95 | $1,494 | 22% | 5.5 | $1,116 | 19% | 5.9 |

| 20% | $5.16 | $1,667 | 23% | 5.3 | $1,254 | 20% | 5.6 |

| 25% | $5.38 | $1,840 | 25% | 5.0 | $1,390 | 22% | 5.4 |

Figure 1. Copper Price Sensitivity After Tax

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_001full.jpg

Significantly Derisked Project at PFS level with Resource Upside Potential

- Strong reserve and resource confidence with 60% of the resources in Proven and Probable and 88% Measured and Indicated categories with over 125 miles (660,000 ft) of drilling in 1,662 drill holes across the Yerington and MacArthur deposits.

- +10 years of extensive metallurgical testwork and modelling completed including over 50 column tests thoroughly assessing performance characteristics across numerous composites and configurations to optimize reliable metallurgical outcomes.

- 6,014 acre-feet/year of secured water rights permitted for mining use for the life of the project.

- Regional infrastructure is in place to support a major mine, with rail, power, highway, airport and proximity to skilled workforce.

- Clear path to permitting with strong eligibility potential for Fast-41 streamlined permitting process.

Strategically Important U.S. Copper Production

- Heap leach operation with solvent extraction-electrowinning (SX/EW), enhanced by Nuton’s proprietary sulfide leaching technology, achieving a project average of 73.2% copper recovery from sulfide ore.

- Run of mine (ROM) oxide ore heap leached with recoveries at the project of 60%.

- On-site production of refined cathode copper for use in U.S. supply chains.

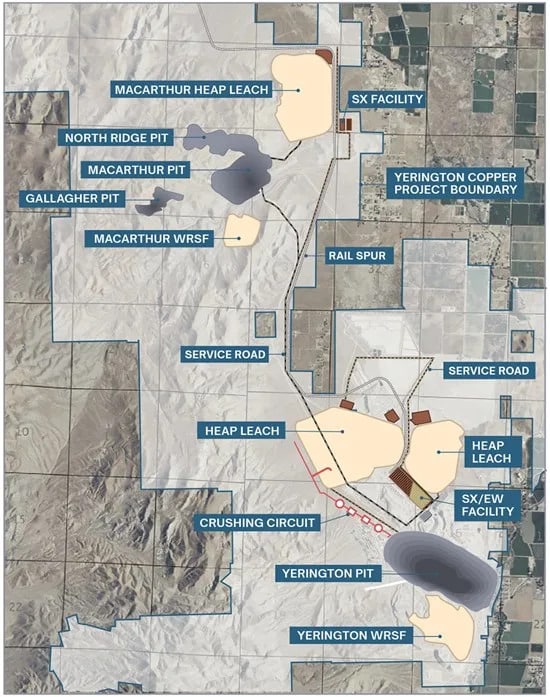

Project Overview

The Yerington Copper Project integrates the Yerington and MacArthur deposits, located in Nevada’s Yerington Copper District, a historic mining region with excellent infrastructure (rail, power, U.S. Highway 95A). The Project benefits from 100% Lion Copper and Gold owned water rights of 6,014 acre-feet/year permitted for mining use for the life of the project and de-risked permitting and mine development. The PFS envisions conventional open-pit mines feeding a heap leach operation, producing LME Grade A copper cathode via SX/EW, with Nuton’s technology enhancing sulfide recoveries. The Project plans to create approximately 400 direct jobs during construction and up to 250 permanent jobs during operations, contributing significantly to the local and state economies.

The Project offers significant environmental benefits compared to traditional copper production. Benefits of the Project include utilizing previously disturbed project facilities area suitable for new mine infrastructure, using pit water for multiple beneficial uses in Mason Valley, zero discharge of water from copper processing operations, lower carbon intensity, and efficiently delivering refined copper cathode directly into U.S. supply chains. These environmental benefits are an important part of the Project being a partner in the Mason Valley to foster growth and diversity in the local economy together with the local stakeholders.

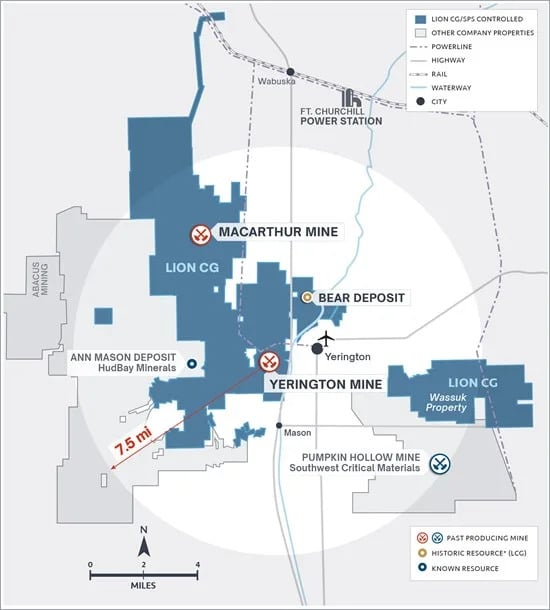

The Project is approximately 70 miles by road from Reno, Nevada, 50 miles south of Tahoe-Reno Industrial Center, and 10 miles from the nearest rail spur of Wabuska. The Project includes both the historic Yerington and MacArthur open pit mines with shared mineral processing infrastructure for operational efficiency. The Project is bordered on the east by the town of Yerington, Nevada, which provides access via a network of paved and gravel roads that were used during previous mining operations.

Figure 2. Yerington Copper Project Overview

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_002full.jpg

Base Case Economics – Based on $4.30/lb Copper Price

| Parameter | Unit | Pre-tax | Post-tax |

| Net Revenue | $USM | 2,914 | 2,315 |

| NPV (7%) (LOM) | $USM | $975 | $694 |

| IRR (LOM) | % | 16.9% | 14.6% |

| Payback | Years | 6.4 | 6.7 |

| Cash Costs1 | $US/lb payable | $1.92 | |

| AISC1 | $US/lb payable | $2.67 | |

| Copper – Payable | Mlbs | 1,443 | |

| Mine Life | Years | 12 | |

| Average Annual Production LOM | Mlbs | 120 | |

| LOM Production | tons | 721,352 | |

1 Total cash cost and AISC are non-GAAP measures and include royalties payable. See reference below regarding non-IFRS measures.

NPV Sensitivities

The sensitivity analysis provides a range of results for the Project when key parameters are varied from their base-case values. The NPV estimate is most sensitive to the copper price.

The PFS uses a base case copper price of $4.30/lb, using the COMEX two-year trailing average copper prices. Project sensitivities were completed on the copper price with a range of $3.25/lb through $5.38/lb:

- At $3.23/lb: NPV(7%) -$21M IRR 7% (Post-Tax).

- At $5.38/lb: NPV(7%) $1.4B, IRR 22% (Post-Tax).

Capital and Operating Costs

The initial capital, expensed over the first 3 years of the Project, amounts to $724 million. The sustaining capital over the remainder of LOM amounts to $1,008 million. A breakdown of capital is presented in the tables below.

| Operating Costs | $USM | $/t Feed | $/lb payable |

| Open Pit Mining | 1,698 | 3.35 | 1.18 |

| Processing | 947 | 1.87 | 0.66 |

| G&A | 124 | 0.24 | 0.09 |

| Total | 2,769 | 5.47 | 1.92 |

| Capital Costs | ||

| Initial Capital | $USM | 724 |

| Sustaining Capital | $USM | 1,008 |

| Total Capital | $USM | 1,732 |

| $/lb payable | 1.20 | |

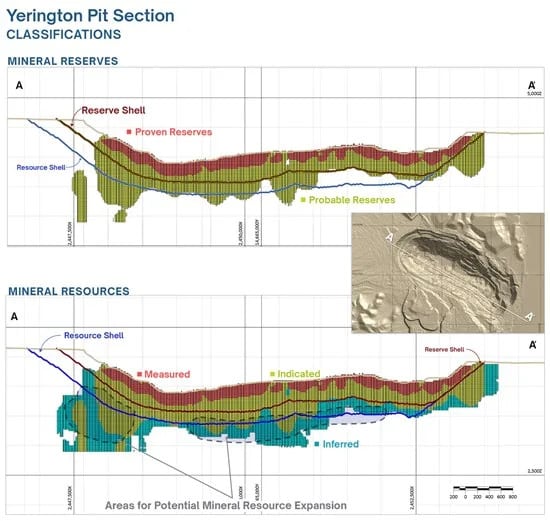

Reserves and Resources

The PFS includes the first Mineral Reserve estimate for the Yerington Copper Project. The PFS is based on the Mineral Reserves only and the reserve estimate is based on pit designs using a copper price of $3.90/lb, with cut-off grades ranging from 0.03 to 0.07% CuT for oxide material and 0.09% CuT for sulfide material.

Mineral Reserves

| Pit Area | Proven | Probable | Total | ||||||

| Ore Type | Tons (kt) | Grade (Cu%) | Copper Mlbs | Tons (kt) | Grade (Cu%) | Copper Mlbs | Tons (kt) | Grade (Cu%) | Copper Mlbs |

| Yerington Pit/VLT | |||||||||

| Oxide | 34,295 | 0.22 | 148.3 | 73,681 | 0.13 | 193.1 | 107,976 | 0.16 | 341.5 |

| Sulfide | 81,037 | 0.30 | 481.1 | 152,761 | 0.24 | 732.3 | 233,798 | 0.26 | 1,213.3 |

| MacArthur Area | |||||||||

| Oxide | 110,224 | 0.19 | 411.7 | 54,553 | 0.16 | 173.5 | 164,777 | 0.18 | 585.2 |

| Sulfide | – | – | – | – | – | ||||

| Total Oxide | 144,519 | 0.19 | 560.0 | 128,234 | 0.14 | 366.7 | 272,753 | 0.17 | 926.7 |

| Total Sulfide | 81,037 | 0.30 | 481.1 | 152,761 | 0.24 | 732.3 | 233,798 | 0.26 | 1,213.3 |

| Total Reserve | 225,556 | 0.23 | 1,041.1 | 280,995 | 0.20 | 1,099.0 | 506,551 | 0.21 | 2,140.0 |

Note: This Mineral Reserve estimate has an effective date of May 31, 2025, and is based on the mineral resource estimates for Yerington and VLT dated March 17, 2025 by AGP Mining Consultants Inc. and MacArthur Area Pits dated March 17, 2025 by Independent Mining Consultants Inc. The Mineral Reserve estimate was completed under the supervision of Gordon Zurowski, P.Eng. of AGP, who is a Qualified Person as defined under NI 43-101. Mineral Reserves are stated within the final pit designs based on a $3.90/lb copper price.

- The copper cutoff grades used were:

Yerington Pit – 0.05% copper (oxide ROM), 0.09% copper (sulfide)

Vat Leach Tailings (VLT) Pit – 0.03% copper (oxide ROM)

MacArthur – 0.05% copper (oxide ROM)

Gallagher Pit – 0.07% copper (oxide ROM)

North Ridge Pit – 0.06% copper (oxide ROM)

- Open pit mining costs varied by area and elevation with waste of $2.53/t, oxide material at $2.49/t and sulfide at $2.22/t. Incremental costs of $0.027/25ft bench were applied below the 4225 foot elevation for waste and oxide and 0.024/t for sulfide material below the 4225 foot elevation.

- Processing costs were based on the use of an acid plant at site with crushing for sulfide material. The processing costs by pit area were:

Yerington Pit – $2.00/t ore (oxide ROM), $4.44/t (sulfide)

VLT Pit – $1.34/t ore (oxide ROM)

MacArthur – $1.67/t ore (oxide ROM)

Gallagher Pit – $2.14/t ore (oxide ROM)

North Ridge Pit – $1.73/t ore (oxide ROM)

G&A costs were $0.49/t ore.

- Process copper recoveries varied by material and area and were as follows:

Yerington Pit – 70% (oxide ROM), 74% (sulfide)

VLT Pit – 75% (oxide ROM)

MacArthur – 55% (oxide ROM)

Gallagher Pit – 54% (oxide ROM)

North Ridge Pit – 55% (oxide ROM)

Mineral Resources (Inclusive of Mineral Reserves)

| Pit Area | Measured | Indicated | Measured + Indicated | ||||||

| Resource Type | Tons (kt) | Grade (Cu%) | Copper Mlbs | Tons (kt) | Grade (Cu%) | Copper Mlbs | Tons (kt) | Grade (Cu%) | Copper Mlbs |

| Yerington Pit/VLT | |||||||||

| Oxide | 37,531 | 0.21 | 157.6 | 96,556 | 0.13 | 257.9 | 134,087 | 0.16 | 417.0 |

| Sulfide | 84,163 | 0.30 | 505.0 | 263,230 | 0.22 | 1,158.2 | 347,393 | 0.24 | 1,663.2 |

| MacArthur Area | |||||||||

| Oxide | 163,333 | 0.18 | 577.8 | 155,086 | 0.15 | 471.6 | 318,419 | 0.17 | 1,049.4 |

| Sulfide | – | – | – | – | – | – | – | – | – |

| Total | |||||||||

| Oxide Total | 200,864 | 0.19 | 735.4 | 251,642 | 0.15 | 729.4 | 452,506 | 0.16 | 1,464.9 |

| Sulfide Total | 84,163 | 0.30 | 505.0 | 263,230 | 0.22 | 1,158.2 | 347,393 | 0.24 | 1,663.2 |

| Total | 285,027 | 0.22 | 1,240.4 | 514,872 | 0.18 | 1,887.6 | 799,899 | 0.20 | 3,129.0 |

| Pit Area | Inferred | ||

| Resource Type | Tons (kt) | Grade (Cu %) | Copper Mlbs |

| Yerington Pit/VLT | |||

| Oxide | 67,338 | 0.11 | 145.8 |

| Sulfide | 67,576 | 0.17 | 229.8 |

| MacArthur Area | |||

| Oxide | 23,169 | 0.15 | 67.9 |

| Sulfide | – | – | – |

| Total | |||

| Oxide Total | 90,507 | 0.12 | 213.6 |

| Sulfide Total | 67,576 | 0.17 | 229.8 |

| Total | 158,083 | 0.14 | 443.4 |

Notes:

- Mineral Resources are reported in situ for the Yerington Pit and MacArthur Pit area and the effective date is March 17, 2025. Mineral Resources for the VLT are surficial and the effective date is March 17, 2025. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. There is no certainty that all or any part of the Mineral Resource estimate will be converted into Mineral Reserves. The Mineral Resource Estimate of Yerington and the VLT was performed by Mr. Tim Maunula, P. Geo of T. Maunula & Associates Consulting and the MacArthur Area Pits by Mr. Herb Welhener, MMSA-QPM, Vice President of Independent Mining Consultants Inc. Both responsible parties are both Qualified Persons under 43-101 standards. All figures are rounded to reflect the relative accuracy of the estimates and totals may not add correctly.

- Mineral Resources of the Yerington pit area are reported within a conceptual pit shell that used the following input parameters: a variable break-even economic cut-off grade of 0.04 % TCu and 0.08% TCu, for oxide and sulfide material respectively, based on assumptions of a net copper price of US$4.22 per pound (after smelting, refining, transportation, and royalty charges), 70% recovery in oxide material, 74% recovery in sulfide material, base mining costs of $2.49/st for oxide and $2.22/st for sulfide, and processing plus G&A costs of $2.00/st for oxide and $4.44/st for sulfide.

- Mineral Resources of the VLT are reported within a conceptual pit shell that used the following input parameters: a break-even cut-off grade of 0.03 % TCu based on assumptions of a net copper price of US$4.22 per pound (after smelting, refining, transportation and royalty charges) and 75% recovery in oxide material.

- Mineral Resources of the MacArthur Pit area are reported within a conceptual pit shell that used the following input parameters: a break-even cut-off grade of 0.05 % for the MacArthur pit, 0.07 % TCu for the Gallagher pit, and 0.06 % TCu for the North Ridge pit. Metal price of $4.22 per pound (after smelting, refining, transportation, and royalty charges); process costs between $1.67 and $2.14/st; and base mining costs for heap tonnage of $2.49/st and $2.53/st for waste,

- Recovery of Total Copper in redox zones of leach cap, overburden, oxide and mixed: MacArthur domain 55%, North Ridge domain 53%, Gallagher domain 54%.

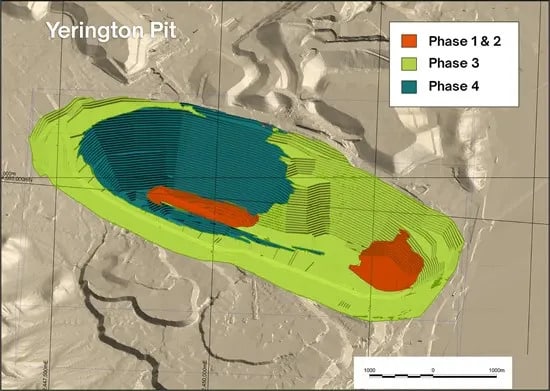

Figure 3. Yerington Pit Long Section

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_003full.jpg

Figure 4. Yerington Pit Mine Phases

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_004full.jpg

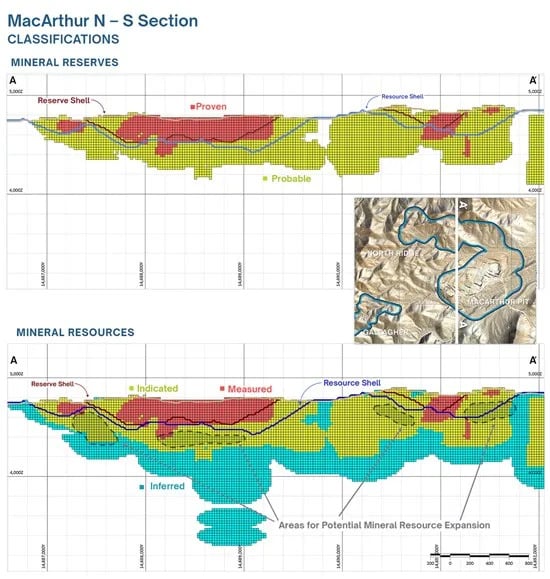

Figure 5. MacArthur Pit North-South Section

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_005full.jpg

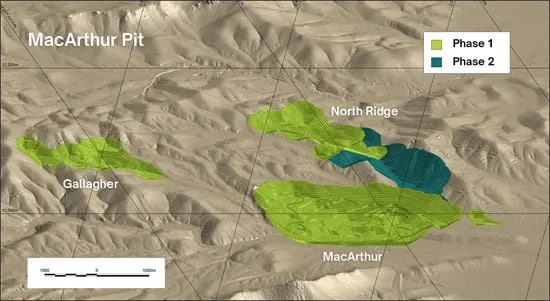

Figure 6. MacArthur Pit Mine Phases

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_006full.jpg

Metallurgy

Nuton™ Technology will be utilized for copper recovery in the form of bioleaching for the Yerington Sulfide Ore. Nuton technology will utilize microorganism assisted acid leach system to extract the copper from the Yerington Sulfide Ore that has been crushed and stacked onto a heap leach pad. Pyrite and Nuton additives will be added to the process at the agglomeration stage to enhance the extraction process. This innovative approach has been demonstrated via extensive column testing, lab testing and modelling to enhance the overall copper recovery for the sulfide ore, offering a lower cost and more water efficient sulfide copper recovery process compared to conventional milling and floatation.

Lion Copper and Gold in partnership with Nuton™ completed extensive column and laboratory testing on the Yerington sulfide material to optimize recoveries from deploying the Nuton sulfide leaching technology. Over 40 test columns were leached by Nuton at their own laboratory to develop both recovery models and fine tune process design criteria. The forthcoming PFS Technical Report will provide additional testwork details and associated results.

Process Description Summary

Copper will be extracted through a heap leach process, followed by SX/EW. Ore will originate from multiple sources which will be stacked and processed on three separate leach pads with two SX circuits. The sulfide and oxide ore from the Yerington open pit will be distributed onto separate heap leach pads but will share an SX circuit. The MacArthur open pits will have one heap leach pad and one SX circuit. There will be a single EW facility for the project co-located with the Yerington SX system.

The Yerington Oxide Heap Leach Facility (HLF) will be ROM truck dumped with a peak placement rate of 83,000 short tons per day (tpd) of new oxide ore and residual stockpiled ore. The crushing, conveying, agglomeration and ore stacking at the Yerington Sulfide HLF is designed for 114,000 tpd to process the peak sulfide ore placement rate of 94,000 tpd. The MacArthur HLF will also be ROM truck dump with a peak placement rate of 142,000 tpd.

The Yerington solvent extraction (SX) systems will handle up to 30,000 gallons per minute (gpm) of pregnant leach solution (PLS). MacArthur’s SX system will be designed to process up to 22,000 gpm of PLS. The shared electrowinning (EW) circuit will process electrolyte from both Yerington and MacArthur with the ability to produce up to 90,000 tons per year of refined copper cathode.

The planned mine life is 12 years, with SX/EW to be in operation for 14 years with the acid plants to be in operation for their life cycle of 19 years. Sulfuric acid production that exceeds project requirements will be sold into the domestic market. The combined copper recovery is expected to be 67.4%.

Figure 7. Yerington Copper Project Copper Cathode Production Simplified Flowsheet

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_007full.jpg

Project Development

Lion Copper and Gold anticipates securing all required permits and authorizations needed to construct and operate the Project within reasonable and normal timeframes. Preliminary permitting schedule estimates that the completion of baseline studies, acquisition of requisite state permits, and the National Environmental Policy Act (NEPA) process necessary for project authorization could be completed in as little as 2.5 years. Furthermore, the Project’s permitting schedule may benefit from the Executive Order (EO) 14241 titled Immediate Measures to Increase American Mineral Production issued in March 2025 to streamline permitting processes for mining projects, particularly those focused on critical minerals.

Figure 8: Development Timeline

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_008full.jpg

Future Opportunities

The Yerington Copper Project covers an extensive strategic land package, including the Bear Deposit and numerous other underexplored targets. While Lion Copper and Gold’s Project is compelling on its own, it creates the potential to act as a catalyst to consolidate with adjacent copper projects.

- Large and scalable processing facility to service and create synergies with several adjacent deposits, projects and operations.

- Utilize and expand on the existing resource base and project infrastructure to extend the life of the Project.

Figure 9. Yerington Area, Including Bear Deposit, Pumpkin Hollow Mine, and Ann Mason Deposit

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1020/261234_fca0639ac4479bca_009full.jpg

Qualified Persons

For the purposes of Canadian National Instrument 43-101, the independent Qualified Persons responsible for preparing the scientific and technical information disclosed in this news release announcing the Study are Michael McGlynn (Samuel Engineering Inc.), Gordon Zurowski (AGP Mining Consultants) Steve Pozder (Samuel Engineering Inc.), John Rupp (Piteau Associates), Tim Maunula (T. Maunula & Associates Consulting), Herb Welhener (Independent Mining Consultants), Marie-Hélène Paré (GSI Environmental) and Adrien Butler (NewFields). The Qualified Persons named herein have reviewed and approved the information in this news release relevant to the portion of the scientific and technical information for which they are responsible.