Bundoora: Where Nuton’s ambition comes to life

April 3, 2024

Thirty minutes north of Melbourne, the second largest city in the Land Down Under, sits the Bundoora Technical Development Centre, the center of innovation for Nuton’s groundbreaking technology.

Surrounded by a lush gathering of trees and close enough to the Australian coast to feel a slight ocean breeze, the Technical Development Centre, known simply as Bundoora by Nuton and Rio Tinto teammates, is located in a beautiful spot.

“People drive through the gate in the morning, and they can’t help but be relaxed and inspired,” says Jared Osborne, General Manager of Technical Development at Rio Tinto. “Kangaroos are hopping around, the occasional big rabbit, some foxes. It’s really quite something.”

Jared says he feels even more energized when he sees the world of immense growth and possibility happening inside Bundoora.

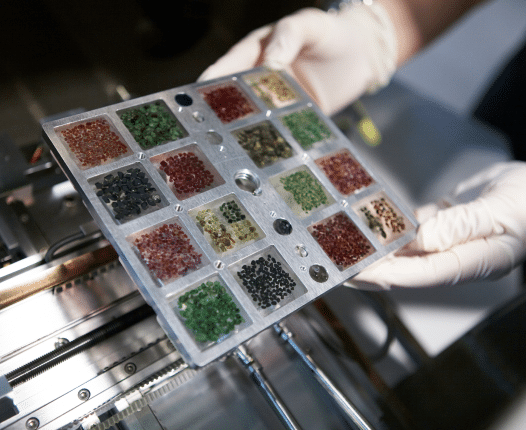

Teams of dedicated scientists, like Jared, have already come so far and achieved so much in nearly 30 years of research and innovation at Bundoora. Back in the early 1990s, Rio Tinto executives at our Kennecott operations in Utah were looking for a solution that could minimize the amount of wasted ore bodies that were unsuitable for traditional processing. The waste was burdensome, economically unviable, and importantly—with notable implications on the environment.

In 1996, a small group of scientists working at Bundoora took a huge leap forward, finding a copper leaching technology that could extract premium quality copper with less water usage and a much smaller carbon footprint. That solution is at the heart of our new Rio Tinto venture, Nuton.

“This was a major breakthrough for a metal that we absolutely need as part of the energy transition. Copper is so vital to it,” says Jared, who joined Bundoora in 1997. “We can make a significant impact on global emissions and the legacy we leave behind with a nature-based solution.”

Over the years, technology and innovation milestones have stacked up at Bundoora. From those first tests in 1996 to small and large column tests in 2006 to a pilot plant in 2012, Bundoora teammates have seen the Nuton technology evolve and ramp up significantly.

Next is to deploy this technology on a large scale, where it can truly create a positive impact on the world. It’ll be an exciting challenge, made possible by the team at Bundoora comprised of some of the brightest minds in the field.

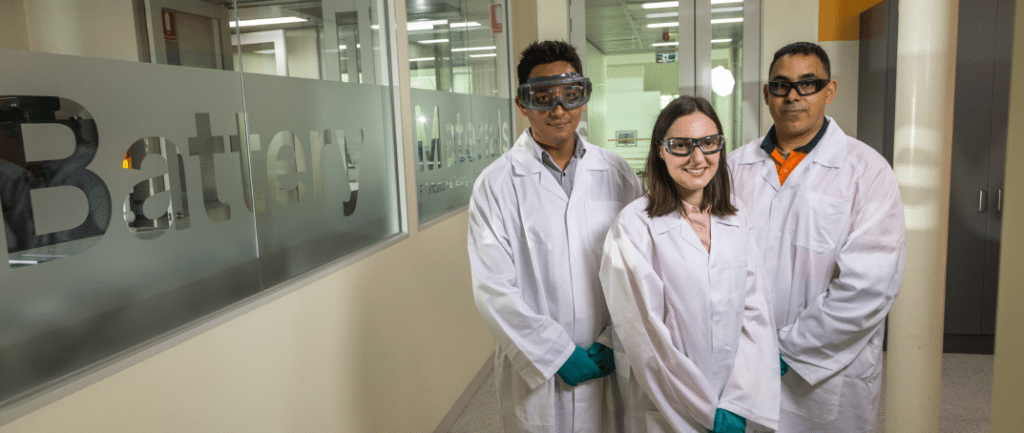

With a diverse team of experts from all over the world, celebrating each other’s culture and championing inclusion are major aspects of the magic at Bundoora. It’s common for teammates to bring in traditional food from their homeland to share with everyone at lunch and for all to truly get to know each other on a personal level.

Those kinds of things are organic and frequent at Bundoora.

“We’ve recruited the best in the world for over 30 years and we’ve ended up with a magnificent mix of people,” says Jared. “It really does feel like a family.”